What is RTLS Technology?

There is a growing interest in RTLS (Real-time Location Systems) as part of the wider Industry 4.0 and “smart manufacturing” discussion. In recent years, RTLS systems have proliferated within the manufacturing, logistics, and engineering sectors. Companies with a better understanding of these technologies and their potential benefits are poised to profit from the increased efficiency, forecasting, and safety associated with their usage.

- What is RTLS Technology?

- How Does RTLS Work?

- The three key aspects

- What are Location Indicators?

- What Are the Use Cases for RTLS Technology?

- What are the Challenges of Indoor Location Tracking?

- Types of RTLS Technology – BLE vs UWB

- Why is Ubisense’s Dimension4 UWB different?

- How are UWB RTLS systems installed/deployed? How much do they cost?

Most RTLS systems are deployed in company ‘owned’ spaces (factories, warehouses, depots, etc) and aim to monitor and improve processes rather than track assets over long distances. There are three main aspects to RTLS:

-

Real-Time Tracking

RTLS technology allows businesses to gain better oversight of where assets are in real time over the course of that asset’s life. This could be products moving along a production line, tools within a factory environment, materials arriving at a warehouse, the location of vehicles, the location of employees – almost anything can be tagged and tracked.

-

Trends & Forecasting

By being able to measure the location and movement of assets it is possible to gain oversight of a process, becoming easier to spot avoidable errors, unnecessary steps, potential shortfalls in resources, employee malpractice, and much more.

-

Geo-fencing

Defining virtual boundaries in three-dimensional spaces has a wide array of applications, including protecting employees from unsafe areas, avoiding contamination, security applications, and more.

Understanding the Difference Between RTLS and RFID Technologies

When it comes to tracking and identifying items, RTLS (Real-Time Location Systems) and RFID (Radio Frequency Identification) serve distinct purposes and are suited to different scenarios.

RFID: Targeting Controlled Environments

RFID technology is ideal for tagging items in environments where movement follows a predictable path. Think of clothing items in a retail store. From the rack to the checkout counter, RFID tags help track these goods. For the system to work, RFID readers are strategically positioned where they can easily detect the tags without obstruction. This technology is perfect for industries where items need straightforward tracking, such as on a conveyor belt in a factory.

RTLS: Real-Time Tracking Everywhere

In contrast, RTLS excels in real-time tracking and monitoring across large or unstructured spaces. It’s designed to locate items without needing close proximity to a reader. Imagine a healthcare facility where equipment needs continuous location updates. RTLS doesn’t just provide location data; the tags can also be equipped with sensors to monitor conditions like impact, tilt, or even temperature changes.

Key Differences

- RFID: Best for predictable, controlled paths where items pass specific checkpoints.

- RTLS: Suited for dynamic environments needing comprehensive and constant tracking.

Each system shines in its respective area, with RFID focusing on point-to-point control and RTLS offering broad-spectrum real-time insights.

How does RTLS work?

![]()

Three key elements

Every RTLS deployment will have three key elements; the transmitters, the sensors, and the software that ties together all the data. Each RTLS provider uses slightly different terminology for their technology, and they will focus on the unique selling points of their particular solution. Below is a generalized breakdown of each of these key system parts:

Hardware

Transmitters (tags, badges, transponders)

Transmitters can vary in size and performance. There are two main types: passive (powered by receiving radio waves from nearby ‘exciters’) and active (requiring power either from a battery or external power source). They are attached to an item or individual, identifying that asset and relaying a signal to sensors.

Distinguishing Features

- Active RFID: Unlike passive RFID, active RFID tags come equipped with a battery. This allows for a greater range as they can transmit signals at higher power levels. Sometimes, these tags also include a processor to pre-process data before transmission, enhancing their capabilities.

- Passive RFID: These tags rely entirely on the energy from radio waves emitted by an external reader. This limits their range but makes them cheaper and simpler to deploy in environments where power sources are unavailable.

Market Considerations

Active RFID stands out for its extended capabilities but comes at a higher cost due to the battery and potential processor. This makes them less prevalent, often caught in the middle ground between the straightforward, cost-effective passive RFID and the more complex Real-Time Location Systems (RTLS), which offer dynamic, high-precision tracking.

By understanding these distinctions, businesses can better choose the technology that fits their specific needs, balancing cost with functionality and operational requirements.

Examples include:

RFID Tags

Perhaps the most common tag. These are passive (ie, require no battery power), cheap, and can be stuck to almost anything, usually used for identifying the asset.

UWB tags

Typically battery powered, these tags send out an ultra-wideband (UWB) signal that is received by sensors. The signal is very short but uses a wide frequency band, allowing highly accurate positioning data with low energy consumption.

BLE & WiFI Tags

Active RFID tags using Bluetooth Low Energy (BLE) or WiFI can send out signals that are recieved by dedicated sensors or existing netowkring infrastructure, offering positioning data but with less precision than UWB.

Smart Devices

Various smart devices can act as transmitters, most notably mobile phones.

GPS Tags

GPS tags use satellites to pinpoint their location. They only work in outdoor areas with a clear line of sight to the sky but do not require any additional infrastructure. GPS tags are less accurate than UWB tags and relatively power-hungry. It is possible to add some infrastructure to a site to enable Real-Time Kinematic GPS that ‘corrects’ the main GPS signal to improve accuracy to within centimeters.

While GPS offers outdoor positioning solutions, Wi-Fi has traditionally been explored for indoor RTLS applications. However, Wi-Fi-based systems struggle with several limitations:

- Accuracy Issues: Wi-Fi typically provides an accuracy of 5 to 10 meters (16 to 33 feet), which falls short for precise location tracking required in many settings.

- Signal Interference: The received signal strength indicator (RSSI), used to estimate distances, becomes unreliable when line-of-sight is obstructed by walls, people, or other materials. This results in noisy and inconsistent data.

- Unsuitability for Modern Needs: Given its lack of precision, Wi-Fi is often considered outdated for RTLS and is rarely successful in achieving room-level accuracy in real-world environments.

By understanding these limitations, it’s clear why newer technologies like UWB or enhanced GPS systems are often preferred for applications demanding high accuracy and reliability.

Global Positioning System (GPS) vs. RTLS

- System Functionality: The Global Positioning System (GPS) is a network of satellites operated by the United States, designed to determine precise locations on Earth. It requires a clear sky view for reliable signal reception, which limits its effectiveness indoors.

- Global Alternatives: Beyond GPS, other countries have developed similar satellite systems, such as Russia’s GLONASS, Europe’s Galileo, and China’s Beidou. These systems function similarly by using satellites to provide location data.

- Indoor vs. Outdoor Use: GPS is predominantly used outdoors due to its reliance on satellite signals. In contrast, Real-Time Location Systems (RTLS) are more suited for indoor environments, offering continuous tracking without the need for satellite visibility.

- Power Considerations: While GPS can sometimes act as an alternative to outdoor RTLS, it is typically reserved for applications needing infrequent location updates due to its higher power consumption compared to RTLS.

- Accuracy Enhancements: Although standard GPS offers limited accuracy, integrating infrastructures like Real-Time Kinematic (RTK) systems can enhance precision significantly, making it viable for applications requiring centimeter-level accuracy.

By understanding these distinctions, users can better decide whether GPS or RTLS is more suitable for their specific location-tracking needs.

Sensors (receivers)

Depending on the types of tags used, the sensors used to track those tags will vary. Most indoor environments requiring more intricate tracking needs than simple passive RFID tags will allow can utilize either active RFID, Bluetooth Low Energy (BLE), or the Ultra-Wideband (UWB) technology.

By tagging relevant assets and positioning sensors around the physical space (the plant, the airplane hanger, the office, etc) sensors can determine the location of each asset at any given time, relaying this information to the relevant software/visualization system. These sensors are usually connected directly to a power source and network (either through ethernet or wirelessly).

Software

There are various software systems associated with RTLS technology, including firmware on hardware items (both sensors and tags) and middleware that interprets the location data stream and connects to external applications.

I is the software in the external applications that will be of most interest to businesses looking to leverage RTLS technology. It will determine how they will interact with and derive benefits from RTLS.

“Depending on which industry one is in, the application software can vary greatly. Many RTLS companies will offer bespoke software applications designed to give you the best possible overview of your enterprise, as well as easy insights into what to optimize. Visualization is usually a core part of RTLS systems.

Some things to look out for in an RTLS software solution are:

- Floorplans and Zone Maps: Can the software incorporate your environment’s current floorplans accurately and to scale?

- Software Practicality: Beyond slick visuals, does it contain the features necessary for your use case?

- Quality Reporting: Are there out-of-the-box analytics and reporting functions to quickly gain insight?

- On-premises or Cloud-based: Options to host the software in the most appropriate way.

- API Connections: The software’s ability to connect openly with existing business systems and databases via API.

- Scalability: Can this software scale as your business grows and operate without bottlenecks as streams of location data are collected?

- Support & Training: How simple is the solution to get started and what support is available for mission-critical applications?

In addition to these software features, the best RTLS solutions also optimize for specific technological qualities that enhance functionality and efficiency. Top-tier systems should possess:

- High Positioning Accuracy: Ideally powered by Ultra-Wide Band (UWB) technology, ensuring precise location tracking.

- Wire-Free Operation: Utilizing low-power mesh networks to eliminate the need for extensive wiring, thus reducing installation complexity.

- Integrated Sensors: Tags equipped with onboard sensors for condition monitoring and process automation, ensuring seamless data collection and operational insights.

When these qualities are combined with the robust software features listed above, businesses can achieve significant savings in both installation costs and time, while also gaining a comprehensive and scalable RTLS solution tailored to their specific needs.”

Does a Central RTLS System Require an On-Site Server?

The necessity of an on-site server for a Central Real-Time Location System (RTLS) depends largely on the type of system in use.

Cloud-Based vs. On-Site Systems

- On-Site Server Requirement: Some traditional RTLS systems rely on on-premise servers to host the Location Engine and Control Tower. This setup requires a physical server infrastructure within your facility, which necessitates regular maintenance and integration with the existing IT system.

- Cloud-Based RTLS Advantage: On the other hand, modern RTLS solutions often operate entirely in the cloud. These systems transmit data from tags and anchors to cloud platforms via gateways, typically using cellular connections like 4G, LTE, or 5G.

Benefits of Cloud-Based Systems:

- Ease of Deployment and Maintenance: Cloud-based RTLS solutions are generally simpler to deploy since they don’t interfere with your local IT environment. The absence of physical servers diminishes the need for continuous server upkeep.

- Efficient Updates: Updates are more streamlined with cloud systems. Updates are implemented once in the cloud, ensuring immediate availability, unlike on-site servers that require individual updates—a process that can be time-consuming and dependent on server accessibility.

In conclusion, while some RTLS systems do require an on-site server, opting for a cloud-based solution can offer significant advantages in terms of simplicity and efficiency.

How RTLS Sensors Enhance Asset Condition Monitoring

Real-Time Location Systems (RTLS) sensors play a crucial role in monitoring the condition of assets by providing continuous insights into their health. These advanced sensors are equipped to oversee various factors that could impact an asset’s integrity.

Key Features of RTLS Sensors in Asset Monitoring:

- Continuous Monitoring: RTLS sensors constantly track the status of assets, ensuring any deviations from normal conditions are quickly identified.

- Condition Alerts: Equipped with smart tags, these sensors can detect physical damage such as falls, impacts, or vibrations. They immediately send alerts, allowing for swift intervention to prevent further damage.

- Environmental Monitoring: RTLS technology monitors environmental factors like temperature and humidity. If these parameters exceed safe levels, alerts are triggered, safeguarding assets from environmental threats.

By integrating RTLS sensors into asset management strategies, organizations can proactively manage and maintain asset condition, reducing downtime and maintaining optimal operational efficiency.

Location Indicators

Location indicators are important pieces of information that help the RTLS software determine the location of the tagged assets. These pieces of information are either sent directly from the tag itself or they are calculated by the sensor. The most common examples are:

Time

There are several different time-based location indicators. Which is used will depend on the tagging technology used and the capability of the sensor network.

TDOA (Time Difference of Arrival)

This method measures the precise difference in the time a signal is received from a tag at one sensor versus another sensor. Because the signals travel at a constant speed, by comparing the time difference a relative position of the tag from each sensor can be found and a location determined. This requires the sensors to have tighltly synchronized timing.

Time of Flight (TOF) Method

TOF (Time of Flight Method) – Measures the time it takes for a signal to be sent from a tag, received at a sensor, and returned to the tag. The distance can then be measured based on the time of this ’round trip’ of the signal and the relative position from a number of sensors determined. Because signals need to be sent and received by the tag, battery performance is typically degraded in this method.

How TOF Works in RTLS

The TOF method involves calculating the travel time of wireless signals, which move at the speed of light. By measuring this time, the distance between a tag and a sensor can be accurately determined. This principle is based on the fact that the speed of light is constant, though it can vary slightly depending on the medium, such as air or water. In most cases, air is the dominant medium, ensuring high accuracy levels.

Achieving High Accuracy

TOF can achieve positioning accuracy within 30 cm, making it a reliable choice for real-time location systems (RTLS). This level of precision is ideal for various applications, from industrial automation to asset tracking. The method’s reliance on precise time measurement ensures minimal error, provided that the signal path is predominantly through air.

By combining these elements, TOF stands out as a robust method for determining location in RTLS, offering both precision and practical applications, while also considering potential trade-offs like battery usage.

Angle of Arrival (AOA)

To gather AOA data, sensors need to understand their orientation relative to one another. As a tag moves around an environment, the sensors calculate the angles at which the signals arrive at their antenna. By measuring angles from multiple sneosrs, an exact positon can be determined.

Received Signal Strength Indicator (RSSI)

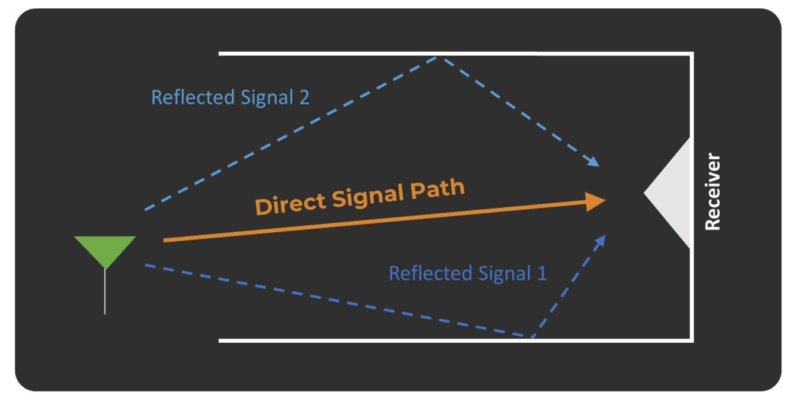

RSSI measures the signal strength coming from the tag to determine its proximity (or distance) to a sensor. This is a common method for RFID tags such as Wifi and Bluetooth. Signals that reflected or blocked can have their ‘strength’ distorted making measurements less accurate.

Comparing Passive RFID and RTLS: Applications and Technology

When it comes to tracking technologies, passive RFID and Real-Time Location Systems (RTLS) serve distinct purposes and are suited to different use cases. Understanding their differences is crucial for selecting the right technology for your needs.

Applications and Use Cases

Passive RFID (Radio Frequency Identification) thrives in industries like clothing retail. It’s ideal for simple identification tasks, thanks to low-cost tags. These tags can trigger alarms at store exits when they pass through RFID reader gates. However, their functionality is limited to short-range detection, often just a few meters or feet from a reader.

In contrast, RTLS (Real-Time Location Systems) are designed for precise tracking of objects in larger areas. They allow for continuous monitoring and can provide real-time data about the location and condition of assets. RTLS is essential in environments where constant, detailed tracking is required, such as in large warehouses or health facilities.

Technology and Limitations

The technology behind RFID involves passive tags that don’t require a battery. This contributes to their affordability, but also limits their capacity. Most RFID tags lack sensors or processing power, which restricts them to identification purposes alone. RFID readers, however, are more expensive and require mains power, adding to the system’s overall costs.

RTLS, on the other hand, often incorporates active sensors capable of tracking a variety of environmental conditions such as temperature or motion. This capability makes RTLS far more suitable for complex applications where detailed data retrieval is critical.

Key Takeaways

- RFID is cost-effective for simple identification, particularly in retail.

- RTLS offers comprehensive real-time tracking ideal for complex environments.

- Consider the scale and data requirements of your project to choose the right technology.

Making an informed choice involves assessing both your immediate needs and long-term goals, ensuring the chosen technology aligns with your operational demands.

What Are the Use Cases for RTLS Technology?

As awareness of RTLS technology grows, the application of this technology to a huge number of industries is becoming more apparent.

Currently, RTLS technology is being used across industries including Automotive, Aerospace, Defence, MRO (Maintenance, Repair, and Operations), Transit Management, Warehousing, Healthcare, and many more. Some of the typical challenges being solved are:

General Asset Tracking

Tracking anything from small parts to heavy equipment within a facility can help stakeholders improve productivity and safety. Optimizing stock levels, preventing equipment overuse, avoiding production bottlenecks, automating tool calibration, and locating missing assets are just some of the benefits that stem from dedicated asset tracking.

Enhanced Equipment Management

By employing Real-Time Location Systems (RTLS), you can significantly reduce search and idle times, ensuring that equipment is readily available when needed. This efficiency not only boosts productivity but also decreases the necessity for additional equipment by up to 20%.

- Preventative Maintenance: RTLS sensors monitor equipment usage, facilitating preventative maintenance and enhancing Overall Equipment Effectiveness (OEE).

- Security and Compliance: Constant tracking provides chain of custody information, ensuring security compliance across operations.

Moreover, RTLS automates processes traditionally reliant on barcode or RFID scanning, reducing errors and improving accuracy. These systems also monitor equipment health, alerting you to potential issues such as impacts, vibration, or excessive heat before they escalate.

Optimized Logistics

Route tracking capabilities within RTLS optimize internal logistics flows, further increasing productivity and streamlining operations. This comprehensive approach to equipment management empowers businesses to maintain a competitive edge while ensuring operational excellence.

Enhancing Material Tracking with RTLS

Real-Time Location Systems (RTLS) take asset tracking to the next level by providing a sophisticated solution for material management. Imagine knowing the precise location of every item in your facility at any moment. RTLS makes this possible, automating inventory counts and offering real-time location updates.

- Streamlining Operations: RTLS ensures that the right materials are available at the right time and place. For instance, if only a single unit of input material is detected at a buffer zone in front of a machine, RTLS can automatically signal the preceding process to supply new material, thus preventing production delays.

- Monitoring Equipment Health: Through RTLS sensor tags, the health of spare parts is monitored in real-time. These sensors can detect damage from falls, impacts, vibrations, and even environmental factors like temperature or humidity, sending alerts to address issues before they escalate.

- Asset Security: High-value assets are safeguarded through geo-zoning or geofencing capabilities. RTLS monitors every movement, alerting stakeholders if assets move out of predefined zones, ensuring a secure chain-of-custody.

By integrating RTLS into your operations, you not only track assets but also enhance overall efficiency and security, paving the way for a more streamlined and productive environment.

In the healthcare sector, RTLS plays a crucial role in managing mobile equipment such as ultrasound machines. This application not only saves time by eliminating the need for staff to search for devices but also improves equipment utilization and reduces capital costs by decreasing the total equipment base required.

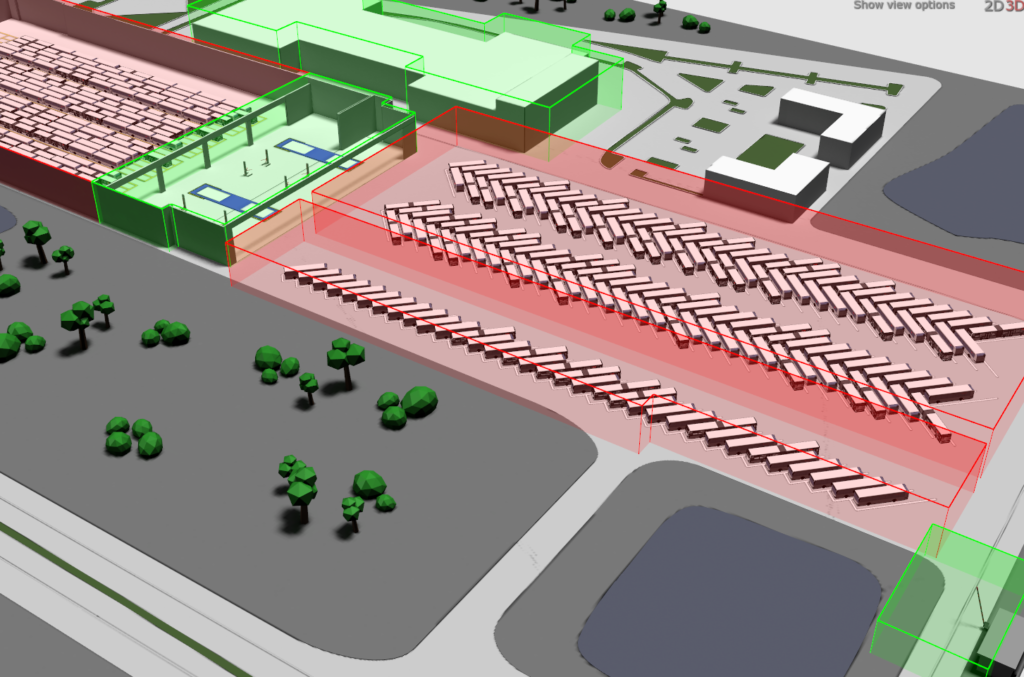

Yard Management

Oversight of WIP (Work-In-Progress) across a facility can prevent missing delivery schedules and lost or damaged products. Space utilization can be tracked to identify opportunities to reduce operational costs, and alerts can prevent WIP from being forgotten or misplaced. By prioritizing different WIP, employees can be notified of optimal work schedules, reducing cycle times.

Transit Management

Accurately tracking the real-time location of vehicles across a transit yard can help to reduce wasted search time and help automate time-consuming processes. Drivers can be guided to the correct parking spaces in coordination with any necessary maintenance tasks. Drivers can be assigned efficiently while the authorization of entry and exit of all vehicles can be tightly controlled. The ability to react rapidly to changing circumstances (including driver and vehicle availability) from a centralized system can also save countless hours while minimizing service interruption.

Aerospace Production

The tracking of aircraft assembly, tooling, kits, and parts can help reduce the time and budget of complex production processes. Tool management, worker safety, and production logistics can all come under the umbrella of one centralized platform.

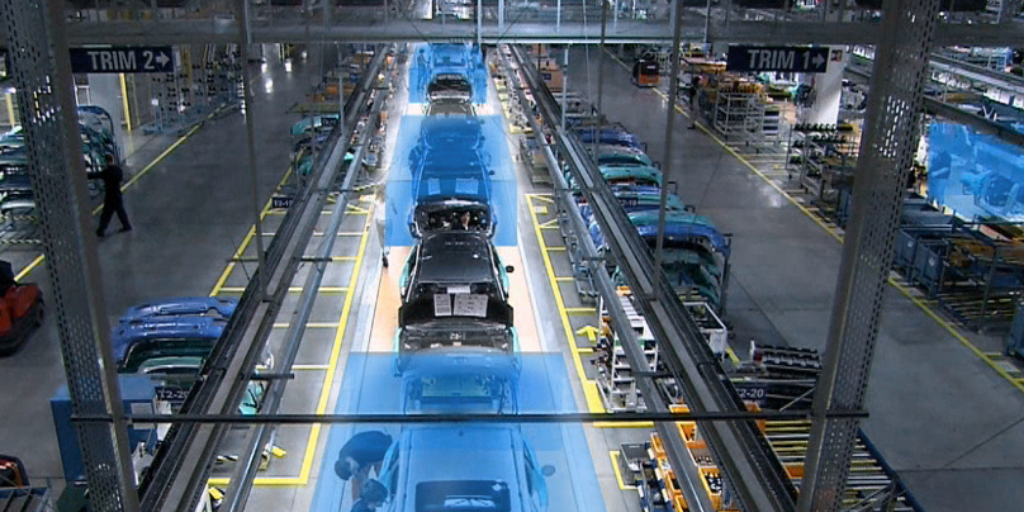

Automotive Assembly

Reducing errors and expensive repair and rework processes, as well as speeding up production cycles, is helping to streamline vehicle manufacturing. By tracking the location of cars and wireless tools on a production line, tool operations can be automated. The dependence on barcode scanning can also be removed, and plant managers can better identify production bottlenecks.

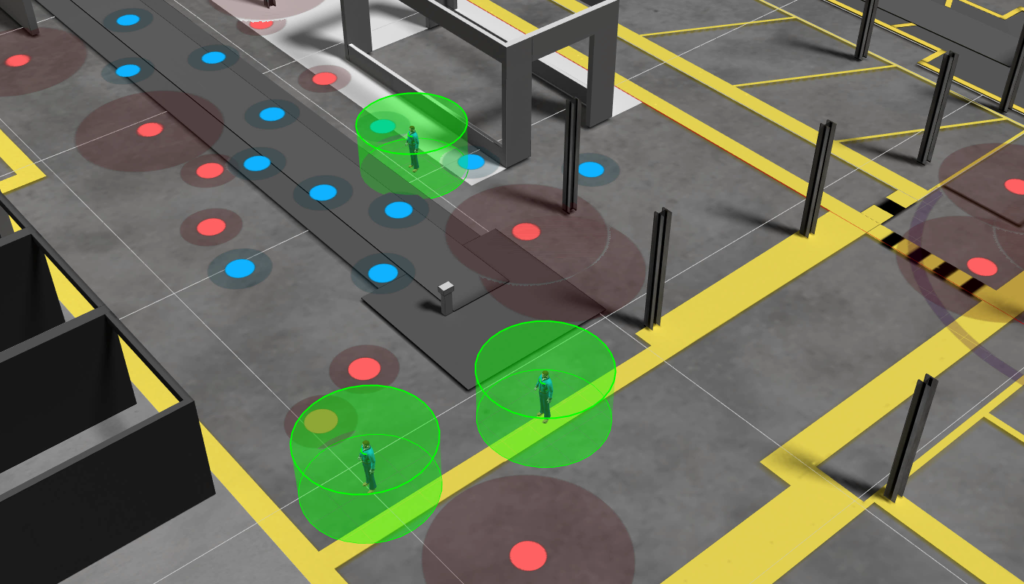

Contact Tracing

Small tags can be carried by employees or attached to their equipment. Due to the high accuracy of some RTLS systems, alerts can be sent when employees come into close contact. The context of specific environments can be accounted for, as well as the length of contact, and current guidelines on social distancing. Careful contact tracing can greatly reduce an enterprise’s downtime during pandemics.

Patient Safety in Healthcare

In addition to equipment tracking, RTLS is pivotal in enhancing patient safety in healthcare settings. This technology tracks patients, especially those at risk of wandering, and generates real-time alerts to safeguard their well-being while reducing the burden on healthcare staff. The ability to monitor patient movement ensures immediate intervention when necessary, significantly improving care quality.

Through these applications, RTLS proves to be an invaluable tool across multiple industries, offering tailored solutions that enhance efficiency, safety, and operational effectiveness.

Comprehensive People Tracking with RTLS

Small tags can be carried by employees or attached to their equipment. Due to the high accuracy of some RTLS systems, alerts can be sent when employees come into close contact. The context of specific environments can be accounted for, as well as the length of contact, and current guidelines on social distancing. Careful contact tracing can greatly reduce an enterprise’s downtime during pandemics.

Beyond contact tracing, RTLS plays a crucial role in enhancing overall safety and operational efficiency. Real-time alerts detect when individuals wander into hazardous or protected zones, providing immediate notifications to prevent accidents. This feature is essential for maintaining a safe working environment.

Moreover, RTLS automates the check-in and check-out process, streamlining contractor timesheets and billing. This automation not only saves time but also ensures accurate record-keeping, boosting productivity.

In emergency situations, RTLS systems offer automatic people counting and positioning, facilitating efficient evacuations and ensuring everyone’s safety. Additionally, task time tracking is integrated to improve work productivity, offering a comprehensive solution that balances safety with efficiency.

By incorporating these functionalities, RTLS becomes an invaluable tool for enterprises aiming to maintain safety, improve efficiency, and ensure compliance with health guidelines.

Monitoring Loading and Unloading in Real-Time with RTLS

Real-Time Location Systems (RTLS) offer a cutting-edge way to oversee the loading and unloading operations of trucks and containers. Here’s how it works:

- Seamless Integration with Operations: As items are being loaded onto a truck or container, RTLS integrates directly with operational processes to ensure everything is tracked instantaneously. This integration allows for the automatic completion of necessary documents, like the bill of lading.

- Immediate Alerts: If an incorrect item is loaded or if there are discrepancies in the load, the system immediately sends out alerts. This helps in quick decision-making and ensures that mistakes are corrected on the spot.

- Departure Verification: RTLS monitors when a load is fully complete and keeps track of whether the truck or container departs with all intended items. If any items are missing, an alert is generated before the truck leaves.

- Data-Driven Assurance: With RTLS, there’s an added layer of assurance in logistics and supply chain management. The system not only tracks the physical movement of goods but also aligns digital documentation in real time, providing a precise overview of operations.

By employing RTLS, companies can enhance their operational efficiency, minimize errors, and streamline their logistics processes, ensuring that goods are accurately tracked every step of the way.

Applications of RTLS in the Naval Industry

Real-Time Locating Systems (RTLS) are revolutionizing the naval industry by enhancing safety, ensuring security, and boosting operational efficiency on vessels. Here’s how RTLS technology is applied:

Safety and Security of Crew Members

RTLS technology automates crew tracking with seamless check-in and check-out processes as members enter or exit the ship. This system provides real-time location data for crew members, which is crucial in emergencies like fires. It can automatically detect incidents such as a man-down scenario, allowing for swift response and increased crew safety.

Equipment Monitoring and Management

Both mobile and stationary naval equipment are continuously monitored using RTLS. The system tracks factors such as temperature, impacts, falls, tilts, and vibrations. This constant monitoring allows for the quick identification of potentially adverse situations, preventing equipment damage and ensuring operational integrity.

Enhanced Fire Detection

In addition to the legacy fire detection systems, RTLS includes stationary sensors that offer a secondary layer of safety. These sensors can give early warnings of fire hazards, adding an extra precautionary measure to protect both personnel and equipment.

With its robust tracking and monitoring capabilities, RTLS plays a critical role in maintaining smooth and secure naval operations.

How RTLS Enhances Vendor Managed Inventory (VMI) and Consignment Stocking

Real-Time Location Systems (RTLS) revolutionize how businesses handle Vendor Managed Inventory (VMI) and consignment stocking by introducing automation and precision.

- Effortless Stock Monitoring: With RTLS, vendors can effortlessly track stock levels at their customer’s sites. This eliminates the traditional manual checking, which is often prone to errors and labor-intensive.

- Automated Process: RTLS seamlessly automates inventory management. As goods are consumed, the system automatically logs these actions, creating real-time data without requiring manual input.

- Instant Replenishment Alerts: The magic lies in RTLS triggering instant notifications when stocks dip below predetermined levels. This ensures that purchase orders for replenishing inventory are systematically generated, keeping operations smooth and preventing stockouts.

- Reduction in Human Error: By reducing the need for constant human oversight in inventory processes, RTLS minimizes the risk of mistakes. This accuracy ensures that businesses can maintain optimal stock levels and effectively manage their supply chains.

Through these capabilities, RTLS not only optimizes VMI and consignment stocking but also boosts reliability and efficiency, providing significant advantages over traditional methods.

The Challenges of Indoor Location Tracking

As a signal reflects off surfaces within an indoor environment, it can distort the signal being received by sensors.

Not all RTLS technology is created equally, and some will be much better than others at tracking assets indoors, especially in complex environments. Shorter signal pulses that use a wider frequency bandwidth avoid any potential overlap from reflected signals. Locations can therefore be interpreted more easily. Ultra-wideband (UWB) uses shorter, wider frequency signals, making it well suited to indoor location tracking.

For more on the accuracy of location systems, see here.

Types of RTLS Technology – BLE vs UWB

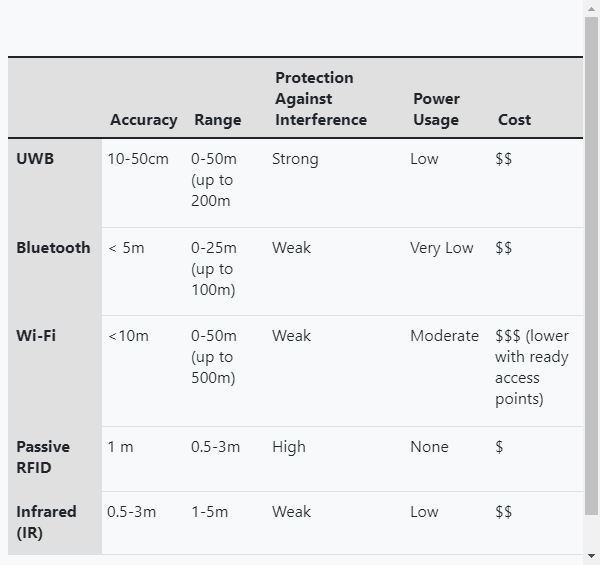

As seen in the Hardware section above, there are many different types of RTLS solutions on offer. Some, like BLE technology, have existed for a long time, while others are comparatively new and offer advantages over older systems. Due to the many potential use cases for RTLS, some systems will be more suitable for some tasks than others.

Some of the more common types of RTLS systems are: Passive RFID, Active RFID, Infrared (IR), Wifi Positioning, BLE (Bluetooth Low Energy), and UWB (Ultra-wideband).

Due to the use of BLE and UWB systems in many Industry 4.0, asset tracking projects, and the potential importance of these technologies in the continued optimization of vast numbers of global enterprises, many people wonder whether UWB is poised to replace BLE. Below, we will take a closer look at these two technologies and see how they compare.

What is Bluetooth Low Energy (BLE)?

BLE is used in a similar fashion to UWB technology, utilizing both tags (usually called Beacons) and sensors (any device with Bluetooth capabilities). Beacons and Bluetooth receivers can be placed in fixed locations and assigned coordinates. When a beacon comes within a set proximity to the receiver, the beacon will deliver its location to the receiver. This response can be forwarded to a BLE system via Wi-Fi where it can be recorded and processed. The receiver’s proximity readings against several beacons will allow the receiver’s location to be calculated.

The Advantages

One of the key advantages of BLE systems Is that they can make use of widely available mobile devices. Most phones and computers already have Bluetooth capabilities, so small-scale systems can be built making use of these devices.

The Constraints

Bluetooth makes use of a specific radio frequency which could make signals prone to interference as radio technologies continue proliferate. Because BLE typically uses either only RSSI or AoA to calculate locations, accuracy and reliabiility can be compromised, particularly in clutter environments. BLE is well suited to real-time zonal tracking.

The BLE Industry

The BLE industry is growing rapidly and is estimated to grow beyond the $16.7B mark by 2026, growing at an estimated CAGR of 19.68%. This is mainly driven by consumer goods rather than industrial applications.

What is UWB (Ultra-wideband)?

UWB is all about precision. By utilizing battery-powered tags (which often come in a variety of shapes and sizes), and carefully positioned sensors, UWB can feed large amounts of real-time data into external software solutions for visualization and data mining opportunities. Not all UWB systems are the same. Those using Time-of-Flight or Two-Way-Ranging can have limited battery performance as the signal needs to be sent and recieved by the tag. Those using AoA methods require multiple sensors to have line of sight to the tag to calculate positions. By combining two different location indicators (TDoA and AoA) in a single sensor system, Ubisense Dimension4 UWB makes extremely reliable and precise location data with long battery lifetimes.

The Advantages

A advantage to this system is it can determine an asset’s location in three dimensions, which has a great number of advantages in industrial settings. The signals are also less likely to interfere with other electronics like phones and Wifi. Due to the low power consumption of UWB tags in systems like Ubisense Dimension4, the batteries don’t need replacing for many years.

The Disadvantages

To gain this extra precision, UWB systems will need more precise calibration than their counterparts and a strong data and timing sncronisation to perfect the real-time tracking information.

The UWB Industry

It is being reported that the Ultra-Wideband industry will be worth $3.2B by 2026, with a CAGR of 19.4% in the 2021-2026 period.

“Increasing popularity of UWB technology among consumers due to its low power requirement, low cost, high data rate transition, and ability to reduce intersymbol interference has significantly triggered the market growth. With increasing adoption of real-time location solutions for indoor imaging systems in industrial applications, to streamline and automate business operations, increasing efficiency and creating new opportunities, the demand for the Ultra-wideband market has gained huge traction.” – IndustryARC

How Ubisense’s Dimension4 UWB is different

Ubisense has sat at the forefront of UWB technology development for decades, making it a unique RTLS provider. The Dimension4 UWB RTLS is best-in-class technology, benefitting from ultra-accurate centimetre-level data, even in difficult environments.

Ultra-Precision

Only DIMENSION4 measures both Time-Difference-of-Arrival (TDoA) and 2-axis Angle-of-Arrival (AoA) of UWB signals in one system, providing up to 5x more location information than comparable systems.

With just two sensors, accurate 3D tracking information is possible, reducing infrastructure requirements and minimizing cost.

Advanced filtering algorithms provide an unmatched ability to cope with obstructed and reflected signals.

Heavy Usage. Many Industries.

Ubisense was founded in 2002, and the company has benefited from decades of experience across industries as diverse as Aerospace, Automotive, Logistics, Defence, Transit, Healthcare, and many more. The time spent in these industries has allowed Ubisense to stress-test its technology and create best-in-class deployment of both the hardware and software elements of its offering.

Many RTLS providers can talk the talk but run into problems during deployment. Ubisense has a proven record of successful deployment.

Tag Quality & Variety

The UB Tag

-

- Small, light, and cost-effective

- Operates in both UWB and BLE modes

- Tough body

- Can operate in -20C to +70C environments

The Mini tag

-

- Perfect for tracking small objects and people

- 40mm x 54mm x 14mm

- Dust and water resistant

- Inbuilt motion detector

- Magnetic reed switch for context-sensitive events

Industrial Tag

-

- Designed for extremes

- Weatherproof

- Can operate in -40C to +85C environments

Tool Tag

-

- Designed to be attached to tools for 3D real-time accuracy

- Robust – designed for harsh industrial environments

- Comes in 2 versions:

- Head Unit: A smaller tag powered directly by the host tool

- Combined Unit: Contains integrated, replaceable A-size battery

Tag Module

-

- Integrates into third-party equipment

- Provides the same, precise tracking ability as other tags

- Possible integrations include high-end torque tools, barcode scanners, and tablets.

Extreme Battery Life

One of the core concerns of UWB users is battery life. Both engineering talent and time spent in the market have allowed Ubisense to develop tag batteries that last up to 15 years, far longer than the competition. They even send alerts when replacements are needed.

How are UWB RTLS systems installed/deployed?

At Ubisense, deploying Ultra-Wideband (UWB) Real-Time Location Systems (RTLS) is a seamless process designed for efficiency. Our expert teams meticulously assess the facility’s layout and operational requirements, strategically placing UWB sensors and tags to ensure optimal coverage and accuracy. The installation involves configuring software interfaces and integrating with existing systems, tailored to specific client needs. With a focus on minimal disruption, Ubisense ensures swift and precise deployment, maximizing the potential of UWB RTLS for enhanced location intelligence in diverse industrial settings. To learn more about our installation process, please contact us now to schedule a short consultation.

Understanding the Costs of Deploying an RTLS Solution

Deploying a Real-Time Location System (RTLS) comes with several costs that organizations need to consider. Here’s a breakdown of where the budget typically goes:

Cabling and Installation

A significant portion, around 85%, of the cost is usually dedicated to cabling activities. This includes:

- Network Planning: Designing the layout for effective coverage.

- Equipment Rental: Bringing in tools like scissor lifts to reach high places.

- Professional Labor: Hiring skilled electricians to handle copper wiring and set up electrical cabinets or POE routers.

Hardware Costs

The expenses for the actual hardware are generally modest in comparison to cabling, accounting for roughly 15% of the installation expenditure. This includes the sensors, tags, and other necessary components for the RTLS setup.

Operational Disruptions

A hidden cost often overlooked is the disruption to ongoing operations. When cabling requires halting business activities, there’s potential for lost revenue during this downtime, sometimes exceeding the direct cabling costs.

Maintenance and Upgrades

Post-installation, ongoing maintenance and scheduled upgrades to the system can be additional expenses to keep the system running optimally.

Wire-Free Solutions

Choosing an RTLS that operates without wires can significantly cut costs by eliminating the need for extensive cabling, reducing both direct expenses and minimizing operational interruptions.

By carefully evaluating these different factors, organizations can make informed decisions that align with their budget and operational requirements.