INDUSTRIES

Aerospace & Defence

Delivering new levels of visibility and quality control in Aerospace and Defence

Ubisense helps organizations with highly complex manufacturing and testing processes improve productivity, increase asset and resource utilization and reduce errors by tracking the real-time movement and interaction of products, people and tools.

Aerospace and Defence

Digital transformation is driving a fundamental change in the Aerospace and Defence sectors. By focusing on their culture, processes and tools, companies will leverage new technologies to become smarter, more productive and lay the foundations for greater competitiveness in a digital world.

Connecting manufacturing systems to real-world business process is fundamental to realising this vision and with SmartSpace, Aerospace and Defence organizations can close a fundamental data-gap between their production or planning systems and the real-world physical activities that drive the outcomes you need.

Process Optimization in Aerospace

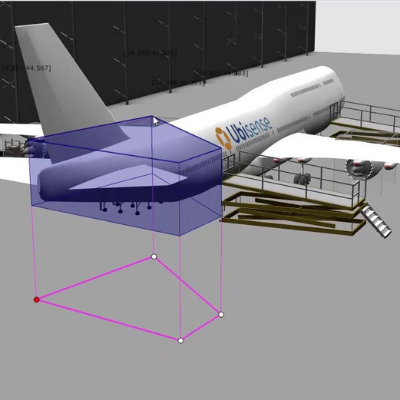

Ubisense Process Monitor for Aerospace provides complete, automated, end-to-end visibility of every stage of production.

The real-time location and movement of aircraft assemblies, tooling, kits and parts are tracked using high-performance Dimension4 ultra-wideband sensors and tags.

As assemblies move into and out of defined workspaces, important location events are recorded and can be used as a trigger to update business systems, people, or machine controls.

MRO

Uncover and reduce invisible process waste in MRO. Ubisense provides a platform to monitor the location, flow and interaction of everything in your complex maintenance, repair and overhaul operations.

The ability to see everything, everywhere gives your existing systems the super-power to find and eliminate previously invisible process waste, increasing productivity and preventing errors.

Solutions for Aerospace and Defence

Tool Management

Locate and manage tools and equipment across large production facilities.

Worker Safety

Define 3-dimensional work spaces and alert people in real-time for unauthorized entry.

Production Logistics

Add real-time location data to logistics management to optimize efficiency.

Our Aerospace Customers

Works in the Real World

Ubisense has thrown everything we know about UWB at DIMENSION4. Not just to make it technically unparalleled, but to make sure it works where you need it.

DIMENSION4 is consistently chosen by people that need it to work in the real-world, even in highly complex environments with certainty of location data, 24/7 for critical processes.

HEAD OFFICE (UK)

Ubisense Limited

St Andrew’s House

St Andrew’s Road

Chesterton

Cambridge, CB4 1DL

United Kingdom

+44 1223 53 5170

NORTH AMERICA

Ubisense America LLC

1630 Welton Street, Suite 1000E

Denver, CO 80202

United States

+1 720 549 7553

EUROPE

Ubisense GmbH

Klaus-Bungert-Straße 5B

40468 Düsseldorf

Germany

+49 211 2297330

Ubisense SAS

52 Boulevard De Sébastopol

75003 Paris

France

+33 1 83 79 06 82