VW. Be the driver of digital transformation with Ubisense.

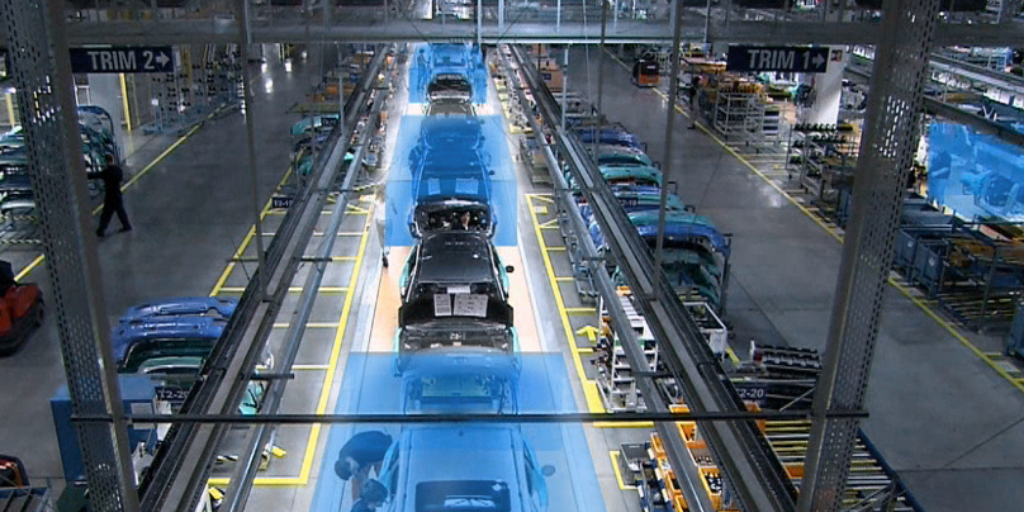

As the Volkswagen Group steps up the pace of digitalization, Ubisense can extend into those places automation finds hard to address – all of the unconnected, manual and moving parts of the vehicle assembly process.

Ubisense tracks the location, movement and interaction of people, parts, tools and products in real-time. Optimising and error-proofing operations while providing the flexibility necessary to build multiple models and variants on the same assembly lines.

Digitalization of the assembly line

Completely remove the constraints of fixed TAKT workstations at Volkswagen by defining infinitely variable and dynamic work zones in software.

Produce multiple product variations on the same line, eliminate idle time waiting for the next product, and complete overrunning tasks without the risk of line stoppages.

- Vary workstation length on the same physical line based on product variant

- Introduce new product lines without expensive line reconfiguration

- Temporarily extend workstations to complete overrunning tasks or allow work ahead on the next product

- Create partially overlapping workstations to maximize the use of space

- Allow online re-work that is controlled and tracked

Solutions for Volkswagen

Tool Control

Directly control wireless tools in real-time on fast-moving or complex assembly lines.

Yard Management

Locate and manage Work-In-Progress (WIP) in real-time across indoor and outdoor storage areas.

Production Logistics

Add real-time location context to traditional parts management to increase efficiency.

Smart industry and electric car demand

The passenger vehicle industry is undergoing unprecedented change, driven by consumer choice and the growing demand for electric and hybrid vehicles.

To respond faster to global market changes, more flexible and efficient production processes are required to shorten innovation cycles and allow the introduction of new products in the shortest possible time.

Ubisense can help VW find new ways to reduce costs, accelerate time-to-market and increase the quality of products and services.

Connecting manufacturing systems to real-world processes and digitizing production logistics, Ubisense location technology can increase the visibility and control needed for the dynamic production facilities across the Volkswagen Group.

Restart operation safely

Ensure employee safety and accelerate return-to-work by monitoring social distancing and person-person and person-object-person contact tracing.

High-confidence separation measurement and contact-tracing

- Tags (carried by people or attached to equipment) are precisely located in 3 dimensions to within 15cm

- Dimension4™ RTLS stability provides high-confidence contact traces uncontaminated by the false positives of less accurate systems

- SmartSpace® tracks contact events, not people, overtime; tag data is completely anonymized until a potential safety risk is identified

AI-driven contagion model

- The SmartSpace® AI-driven contagion model operates well beyond simple separation measurement, using detailed models to understand movement and interaction of people over time and within the context of their environment

- The contagion model is quickly and easily adaptable as transmission mechanisms become better understood

Locate and manage Work-In-Progress (WIP) at VW

Locate

- Instantly find finished or part-finished products that are widely dispersed around site with precise searches.

- See all Work-In-Progress (WIP) across your facility with a real-time, browser-based map.

Manage

- Set alerts for ageing or forgotten WIP to avoid missing delivery schedules and loss or damage to products.

- Create a digital-twin of your yard with real-time movement of products to identify process bottlenecks.

- Track actual space utilization over time with dashboards and identify opportunities to reduce capital and operational costs.

Volkswagen vision. Our mission.

We are proud to be a trusted adviser to the biggest and most premium global automotive companies in the world, offering in-depth knowledge of the industry in which we operate and the challenges our customers face, at every level of the organisation.

Our solutions are based on our powerful, sensor-agnostic enterprise platform that uses location to deliver a real-time digital twin of our customer’s physical operations, proven to drive quality, increase productivity, manage complexity and reduce costs.

Improve quality both on and off-line

Ubisense has a long track record of helping premium automotive OEMs improve the quality of products both on the assembly line and in off-line repair and rework.

- Error-proof assembly operations by automatically matching cordless tool operations to product specification in precisely defined work zones.

- Possible to bolt-level accuracy to control tightening sequences for critical fastenings

- Enable directed, controlled and audited on-line rework for mobile operators to correct defects before the end of assembly

- Orchestrate the location, movement and sequence of tasks in repair and rework processes using real-time data, not out-of-date spreadsheets

Ubisense Success Story

You’re in good company.

Ubisense is proud to be a trusted adviser and supplier to some of the biggest and most forward-thinking automotive companies in the world

Location Data Integration

Ubisense Dimension4™ Real-Time Location Systems (RTLS) uses not just Ultra-Wideband (UWB) but can integrate any location sensing technology to offer extended use cases across the automotive plant.

Bluetooth Low-Energy (BLE) or RFID can be integrated in the same system for high volume parts and materials tracking to optimize production logistics, optical vision and laser systems offer millimetre level accuracy for critical fastening and tightening sequencing, and GPS extends coverage outside to storage and test areas.

Application Integration

Ubisense connects to any existing system of record, including ERP and MES to update planning and execution with real-time events and activity, and tool control systems to ensure correct operations are enabled, tracked and audited to reduce errors and improve quality.

Extensible APIs support any non-typical integration through various interfacing technologies including REST services, .NET, and direct RDBMS integration.

Reporting and Dashboard

Build and customize process and KPI reports from large volumes of historical and real-time data. Move from out-of-date excel planning documents to real-time systems offering insight and optimisation of off-line repair and rework processes like Aston Martin

Highlight process inefficiencies and give decision makers valuable business insights into performance, trends and previously hidden processes.

How to get started

Speak to one of our automotive experts to define the sensor and tag coverage required to enable the solution you need; wireless tool control, production logistics, yard management and repair/rework optimisation.

Software integrations with ERP, MES and tool controllers enabled, and reporting and dashboards easily configured whether on-premise or in the cloud.

Hardware installation and configuration with Ubisense and local partners, including automated sensor calibration and verification.

Ongoing tech support and training to ensure continued performance and optimisation for busy, dynamic and complex manufacturing facilities.

Technology

World-class technology specifically designed to operate in complex and dynamic automotive plants with a proven track record of reducing costs and increasing efficiencies.

Advisory

Trusted advisers offering deep understanding of digitizing the automotive assembly processes from long-standing relationships with leading global OEMs.

Customer Service

Strong customer references demonstrating compelling return on investments and a global service network meaning local support where you need it.

Zero Interruption

A solution architected with automotive manufacturers in mind, with the ability to install, configure, test and deploy without disruption to ongoing operations.

Additional features

On-demand whitepaper: 2025 Automotive Trends: Navigating Change Through Efficiency and Innovation

Whitepaper 2025 Automotive Trends: Navigating Change Through Efficiency and Innovation The automotive industry is at a

The Future of Automotive Operations: Driving Innovation Through Digital Transformation

The Future of Automotive Operations: Driving Innovation Through Digital Transformation The automotive sector is accelerating toward a transformative era

Ubisense Declares the Death of Lean Manufacturing: Why Real-Time Data is the New King in Automotive

Ubisense Declares the Death of Lean Manufacturing: Why Real-Time Data is the New King in Automotive For decades, lean

Quality Assurance in Auto Manufacturing: A Guide to End-of-Line Inspection

Quality Assurance in Auto Manufacturing: A Guide to End-of-Line Inspection In the intricate realm of auto manufacturing, where precision

Assembly Line Rework – Ubisense Virtual Conference 2023

On-demand Webinar Assembly Line Rework - Ubisense Virtual Conference 2023 On-demand recording from the Ubisense Virtual Conference 2023, first

Assembly Line Tool Control Demo- Ubisense Virtual Conference 2023

On-demand Webinar Demo - Assembly Line Tool Control - Ubisense Virtual Conference 2023 In this session, Elif Kaya (Presales

HEAD OFFICE (UK)

Ubisense Limited

St Andrew’s House

St Andrew’s Road

Chesterton

Cambridge, CB4 1DL

United Kingdom

+44 1223 53 5170

NORTH AMERICA

8400E Crescent Pkwy

Suite 648

Greenwood Village

Denver, CO 80111

+1 720 549 7553

EUROPE

Ubisense GmbH

Klaus-Bungert-Straße 5B

40468 Düsseldorf

Germany

+49 211 2297330

Ubisense SAS

52 Boulevard De Sébastopol

75003 Paris

France

+33 1 83 79 06 81