Indoor asset tracking is a system that tracks the location and movement of assets in indoor environments like hospitals, factory floors, and offices. Challenges like limited line-of-sight, interference, attenuation, and accuracy requirements make indoor asset tracking more difficult than outdoor asset tracking.

This article will explore some of the technical considerations for tracking assets indoors. Let’s start with a brief overview of technologies used for indoor asset tracking.

Indoor Asset Tracking Technologies

Indoor asset tracking technologies are a range of solutions that includes Ultra Wide Band, Bluetooth Low Energy, RFID, and GPS. This section presents a bird’s eye view of the most common technologies. For a comprehensive overview, please refer to our guide to asset-tracking technologies.

- Ultra Wide Band (UWB) – UWB uses a wide frequency range to transmit data over short distances (typically less than 100m.) UWB location tracking systems can track with centimeter-level accuracy. UWB tags are relatively low power (Ubisense’s UWB tags have a battery life of up to ten years) and come with power-saving features like deep sleep. These features make UWB a useful technology where precise location and low power consumption are essential.

- Bluetooth Low Energy (BLE) – BLE is a radio location tracking technology like UWB. However, It has lower bandwidth, range, and accuracy. BLE location tracking systems have meter-level accuracy and a range between thirty to sixty meters. BLE tags have long battery life. They are ideal for assets that need room-level tracking accuracy.

- Other Indoor Asset Tracking Technologies – Barcodes and passive RFID tags can be used when accuracy, range, and real-time location tracking are not required. RFID tags are cheap and effective for tracking the movement of assets via waypoints. Wi-Fi location tracking is a real-time but low-accuracy system that can piggyback on existing Wi-Fi infrastructure. This makes deploying Wi-Fi location tracking inexpensive and unobtrusive.

These are perhaps the most popular asset tracking technologies but there are more available. For a more comprehensive understanding of these technologies, please refer to our guide.

What to Look for in an Indoor Asset Tracking Tag

Accuracy, precision, and range are key elements of a tracking tag. However, other factors, such as the battery, form factor, and mounting, are equally important and will be discussed in this section.

Battery

Changing batteries on tracking tags is time-consuming and interferes with the use of the asset. Sometimes, it may not even be possible due to the asset’s build. Therefore, it is important to understand indoor asset tracking tags’ power requirements and battery life.

One should also look for power-saving features like deep sleep and flexible update rates.

A flexible update rate allows the tag’s update rate to be adjusted depending on the tag’s activity. The update rate is low when the tag is stationary, thus preserving power. However, an in-built motion detector increases the update rate for greater accuracy when the tag is in motion.

Another factor to consider is if the battery is user replaceable.

Ubisense’s tags utilize a range of batteries, such as lithium thionyl chloride (LTC), C-size lithium battery, and lithium coin cell batteries. The batteries on some of our tags can last for over a decade.

The following list provides the estimated battery life of different asset tracking tags:

- UWB – 10+ years

- BLE – 8+ years

- Active RFID (UHF) – 1 to 3 years

- Wi-Fi – Less than a year

Ubisense’s battery management module makes it easy to manage tag batteries. Some mention-worthy features are.

- Battery replacement warning and imminent failure warning.

- Battery usage monitoring.

- Protection against accidental deep sleep mode activation.

Not all active tags come with an in-built power supply. For example, Ubisense’s UWB tag module needs an external power source.

Configuration

Asset tracking tags are configured before use. The tag’s configuration may include setting up the update rate, motion detection threshold, and other settings related to its operation. If the use case requires frequent configuration changes, having a tag that can be reconfigured remotely will be useful. For example, the UWB Tag Module has a 2.4 GHz narrow-band configuration channel that enables remote configuration.

Dual Mode Tags

Indoor environments are often cluttered, causing signal attenuation and multipath interference. Dual mode tags simultaneously use two tracking technologies, say UWB and BLE. This enhances the accuracy of indoor asset tracking.

Mounting

In addition to selecting the appropriate sensor for a tracking application, one must ensure that it fits into the designated mounting space. One must be aware of mounting restrictions and select an appropriate mounting method accordingly. Some common mounting options are screws, Velcro® mounting, magnetic mounting, and custom mounting.

Form Factor

The tag form factor must be considered when selecting a tracking tag. The form factor of the tag depends on the tracking technology and tag features. The form factor of the tag determines which assets it can be used on.

Tool management and control require small tags that are unobtrusive and discreet. Head & battery unit tools tags and integrated tool tags have a form factor suitable for tracking tools. Tags for tracking people should also be ergonomic and comfortable to wear.

Environmental Protection

Tags should be designed to be rugged for use in harsh industrial environments. They should be mechanically robust and dust & water-resistant. Always check the IP rating of the tag. IP stands for “Ingress Protection” and indicates how well a product protects against the entrance of solid or liquid particles, such as dust and water.

For example, UB-Tag™ has an Ultrasonically-welded case rated IP67 and IP69K.

The number “6” in IP67 and IP67K indicates complete protection against dust over an extended time and against contact with objects greater than 1mm in diameter, such as a wire or a small tool.

The second number indicates protection against water ingress. The code “7” means the device is protected against short periods of immersion in water up to a depth of up to 1 meter. The code “9K” indicates that the tag is protected against high-pressure and high-temperature water jets from all directions.

Now that we have explored some key features of asset tracking tags, let’s examine some use cases for tracking assets indoors.

Tracking Forklifts

Let’s start our section on tracking assets indoors with the interesting case of tracking forklifts. Tracking a few critical assets over a large area is a common requirement in many industries.

Ubisense has deployed RTLS for tracking forklifts across factory floors with high accuracy. UWB is an obvious choice for high accuracy and real-time tracking of assets. Ubisense’s Dimension4 measures both the Time Difference of Arrival and the Angle of Arrival, therefore Ubisense’s technology needs just two UWB sensors to track a UWB tag. However, when the coverage area is large, the cost of sensors can quickly add up.

With some out-of-the-box thinking and clever engineering, the team at Ubisense has flipped the tracking solution on its head. UWB tags cost a fraction of what UWB sensors cost, so the team decided to equip each forklift with a UWB sensor and fixed tags around the factory floor.

The RTLS hardware and software were rewired to use the tags to track the sensor, effectively making the “tracker” the “tracked.” This reduced the cost of the system while maintaining accuracy and real-time performance.

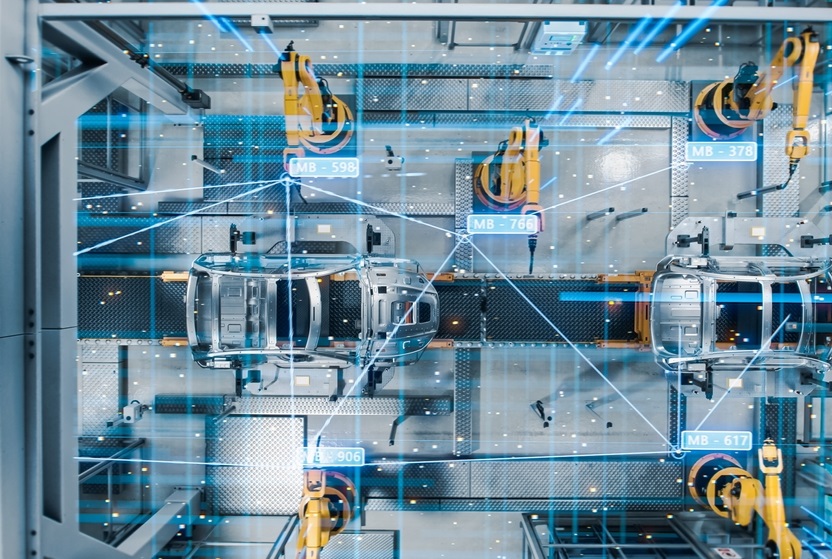

Tracking Production Line Processes

Assets are not the only things that need to be tracked. As production lines become increasingly complex, tracking processes have become essential. Using software and location tracking to visualize production lines as a virtual 3-dimensional map can help track & optimize performance. The benefits are:

- Allow workers to work ahead or compensate for lost time.

- Introduce new product variants without expensive assembly line reconfigurations.

- Design workstations that overlap to maximize the use of the available physical space.

- Enable on-line rework by adding new temporary workstations specifically for remedial tasks.

The benefits are numerous:

- Less space needed for production operations

- Less idle time between tasks

- Fewer line stops

- Fewer errors and defects

- Shorter time to introduce new models or variants.

Tool Tracking and Management

Tool tracking is becoming increasingly common in factories and shop floors to locate tools, monitor them, and control their usage.

Asset tracking lets workers quickly locate tools. Modern tools management systems like Ubisense’s support tailored searches and a user-friendly, web-based map, thus eliminating wasted search time. This helps to improve process efficiency by correctly organizing tools and equipment for your processes.

Asset management systems can be used to create alerts for tools based on their status, location, or maintenance. For example, alerts can be generated for tools that are overdue for maintenance, stored incorrectly, or located outside of designated zones.

Tool management systems can help protect operations against Foreign Object Damage (FOD) by automating and error-proofing tool check-in and check-out procedures. They allow for easy and quick end-of-shift tool audits by taking a real-time inventory of equipment located on the shop floor or in storage. They also help to ensure that tools are always present and accounted for.

In addition, tool management systems can be integrated with production system databases to provide real-time feedback on tool usage. This helps to identify bottlenecks, detect malfunctioning tools and optimize processes.

Conclusion

Indoor location tracking is becoming increasingly important for businesses. Ubisense offers sophisticated tracking solutions to help businesses optimize and speed up the physical flow of assets and processes. To find out more about our location-tracking technology and solutions, click here.