INTRODUCTION

In this series of Blogs, I explain how using digital process twins can revolutionize MRO efficiency. I discuss how the concept of the Digital Process Twin, having been perfected in assembly plants across aerospace and automotive manufacturing, is now being applied to MRO operations.

The Internet of Things is a much-discussed topic, but people aren’t things, and nobody sells “smart, connected wing stands” so how do IoT concepts apply to MRO hangar operations? Similarly, Industry 4.0 promises revolutionary changes in manufacturing, but what lessons, concepts and technologies can transfer to the MRO industry? How does the Smart Factory inform the Smart Hangar?

Ubisense is a company that transforms physical spaces into smart spaces, with a long track record of bringing manufacturers proven gains in quality, cost, and productivity. Our SmartSpace® platform monitors the physical flow of complex operations creating a real-time “digital twin” of the process. This Digital Process Twin provides deep situational awareness which empowers people to make more insightful decisions, and business systems to operate with foresight and certainty.

Industry 4.0 and IoT have shown important value in manufacturing operations, and platforms like SmartSpace have filled the data gap, connecting those concepts to complex manual processes. Now MRO operations are beginning to leverage those innovations and solutions to create the Smart Hangar. The concept of the Digital Process Twin, so successful in bringing order, repeatability and efficiency to manufacturing operations is directly applicable to MRO processes.

Ubisense’s decade-plus of experience in deploying mission critical solutions is now being sought by MRO operators to guide them through the steps of plant digitization. Our SmartSpace platform extends existing business systems and creates new possibilities for improving compliance and turnaround time.

THE KEY PILLARS OF MRO

As discussed in the previous Blog, the Digital Process Twin is what we are creating in the MRO environment and to do this we need to understand how all the key pillars of MRO interact with one another to help define and monitor the process.

The pillars of MRO are:

- The tasks that should be managed within the MRO processes

- People and the various skills that are required to perform the tasks

- The tooling required for each task and

- The material required

Each of these pillars is discussed in further detail highlighting some key components and areas where value can be realized.

1. Tasks

Looking first at the tasks, here are some examples of how tasks can be scheduled and coordinated effectively within an environment, where the user creates the rules within SmartSpace to manage what gets done, when and how.

- Plan efficiently using actual data

- Record actual vs planned activities

- Record findings over time, resource, skills and materials for information that can be used in future planning

- Execute consistently

- Save the plan template for training, insight and future use

2. People

This is about making sure that the right people are available and, if the business allows it, to track those people to know where they are. In most cases, people get allocated to particular work orders or tasks so it’s possible to know where they should be. Here are a few examples of what can be captured and monitored to review what is working well and what is not working well within that facility and returning the value through the business.

- Check/monitor skills required to complete planned tasks

- Check/monitor currency of qualifications of those with correct skills

- Allocate specific technicians to tasks

- Manage and control enablement of Electronic Task Cards for technicians on mobile devices

- Record time spent on tasks

- Sign completion/closure of tasks

3. Tooling

This can be managed through a digital twin and is one area where many of those adopting this technology start, by managing how they issue the tools out and where the tools are to ensure that they are always controlled. Again, here is a sample list of what can be achieved to ensure that tooling is available, conformant and able to be located:

- Ensure tooling is serviceable

- Ensure tooling is available

- Deliver tooling to zone prior to need

- Confirm use of tooling

- Return tooling to storage

With ground support equipment (GSE) or larger more expensive tooling, SmartSpace can help to understand how these tools are managed including their utilization. Another example could help manage tooling: when a tool is issued to one individual, instead of going back to the tool store, it can be transferred to another individual but still be controlled through the inventory management process. This is possible because, with SmartSpace, the user knows where the different people are and knows where the tools are so that people can exchange tools easily and in a controlled manner within this environment. With real-time tracking of GSE, a team lead awaiting a specific GSE can be notified instantaneously when it becomes available and claim it faster, thus reducing the overall time-span of a repair.

4. Material

It is always important to know where material or components are. Is it at the right place at the right time so that the user can pre-draw the material and get it to the point of use in a timely manner? The solution can also manage the store so that the business knows how much material is available (how many consumables or other types) and can manage that in real time as well as pull all that information together. Again, here is a short list of aspects of material management that need to be considered:

- Check material is available, if not place an order

- Prepare material for delivery to zone just in time but prior to demand

- Confirm consumption of material and recover possible lag time in replenishment

- Arrange for return to store of unused stock

SINGLE PLATFORM

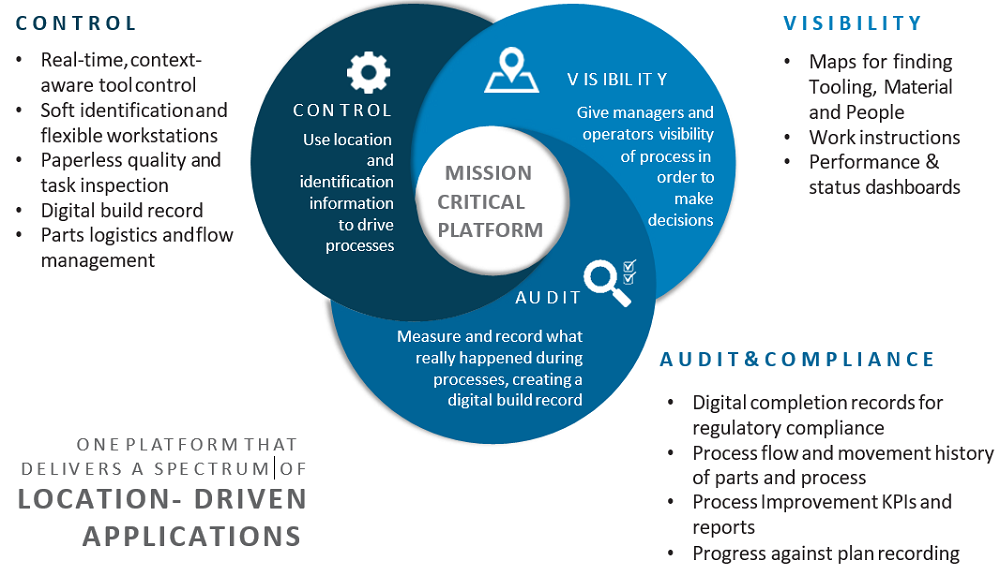

As always, the trick to digitizing a hangar is to find a single solution that solves multiple problems, rather than a unique solution to each problem. SmartSpace is architected as just such a platform that delivers visibility of all internal processes and activities, as shown in the figure below.

There are three main categories of value that a platform like this can deliver:

- Visibility

- Error-Proofing

- Audit

1. Visibility

Adding a location context to other business data enables a very intuitive view of both assets and processes. Clearly a map of tools, material and other assets is helpful when gathering the necessary equipment for a task, but a simple view of tasks allocated across that map can add a valuable context to workflow. In one example, a simple map of task status as allocated around an airframe provided insights that a simple table could not. Very simply, a “bird’s eye view” of the hangar is a very intuitive way to assimilate process status at a glance.

2. Error-Proofing

SmartSpace includes a rules engine that allows users to program expected process flow and leaves SmartSpace to detect errors and deviations. In this mode SmartSpace can be thought of as a wingman, constantly monitoring the hangar and drawing your attention to any issues that might affect compliance or turnaround time.

3. Audit

By monitoring the flow and interaction of critical assets against tasks, detailed automatic compliance records can be established. This not only supports process audit, but equipment utilization monitoring: the historical flow and use of equipment informs future equipment needs, as well as optimal storage and routing (5S).

Once we have built the MRO Digital Twin of your business it is now possible to start driving real value. In the final Blog of this series I will detail a number of use cases and areas where MRO businesses can start to drive real value.

Do you want to learn more on How to Improve Business Efficiency in an Aerospace MRO Environment? Watch Dr Hugh Revie’s On-Demand Webinar on the same topic: WATCH NOW

Written by Dr Hugh Revie, Sales Director Aerospace EMEA at Ubisense

Hugh is one of the world’s leading experts in the Aerospace industry. Hugh has now been working in Aerospace for more than 30 years and, prior to joining Ubisense, started his career in aviation after graduating with a doctorate in Engineering and, initially working for British Aerospace. Around 18 years ago, he created his own company, CoreData Limited, focused on helping airlines, MROs, OEMS and aircraft supply chain companies with solutions that could drive value from the large amounts of data they were accumulating. He finally sold the company to Rolls Royce. Since then he has been working with customers to improve efficiencies by using their own data and continues to do this with Ubisense.