INTRODUCTION

In this series of Blogs, I explain how using digital process twins can revolutionize MRO efficiency. I discuss how the concept of the Digital Process Twin, having been perfected in assembly plants across aerospace and automotive manufacturing, is now being applied to MRO operations.

The Internet of Things is a much-discussed topic, but people aren’t things, and nobody sells “smart, connected wing stands” so how do IoT concepts apply to MRO hangar operations? Similarly, Industry 4.0 promises revolutionary changes in manufacturing, but what lessons, concepts and technologies can transfer to the MRO industry? How does the Smart Factory inform the Smart Hangar?

Ubisense is a company that transforms physical spaces into smart spaces, with a long track record of bringing manufacturers proven gains in quality, cost, and productivity. Our SmartSpace® platform monitors the physical flow of complex operations creating a real-time “digital twin” of the process. This Digital Process Twin provides deep situational awareness which empowers people to make more insightful decisions, and business systems to operate with foresight and certainty.

Industry 4.0 and IoT have shown important value in manufacturing operations, and platforms like SmartSpace have filled the data gap, connecting those concepts to complex manual processes. Now MRO operations are beginning to leverage those innovations and solutions to create the Smart Hangar. The concept of the Digital Process Twin, so successful in bringing order, repeatability and efficiency to manufacturing operations is directly applicable to MRO processes.

Ubisense’s decade-plus of experience in deploying mission critical solutions is now being sought by MRO operators to guide them through the steps of plant digitization. Our SmartSpace platform extends existing business systems and creates new possibilities for improving compliance and turnaround time.

THE IMPORTANCE OF LOCATION CONTEXT

I start by highlighting the missing element of many IoT implementations: the context of asset location and movement. Having highlighted the value of that additional context, I will apply that to MRO operations to understand the benefits in planning, the ability to react to issues, and consequently reduced turnaround time.

Like the assembly operations where the Digital Process Twin was pioneered, MRO operations are complex feats of motion and synchronization. Execution is the process of getting the right people with the right tools and the right material to the right place at the right time, and planning is the art of choreographing that dance. It’s a complex interplay of moving parts that gets quickly tangled and off track the moment anything unexpected happens. And something unexpected always happens.

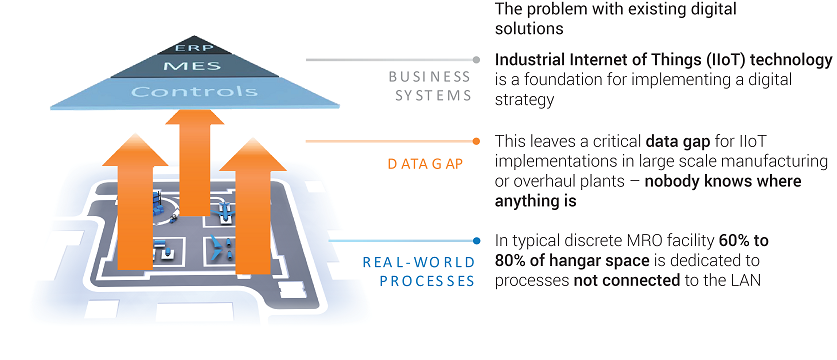

The figure below offers a perspective on today’s position in most MRO companies showing business systems at the top, including planning and control systems as well as systems of record. At the bottom is the real world: the hangar floor and all the activities that go on there. The top-level systems know what needs to get done, and how to do it, but they don’t know how processes are progressing.

This is the data gap: there is no way of knowing what is happening on the hangar floor until after it’s happened, or until after it hasn’t happened. Only limited historical information is fed back into the systems with no real-time warnings when processes deviate from plan.

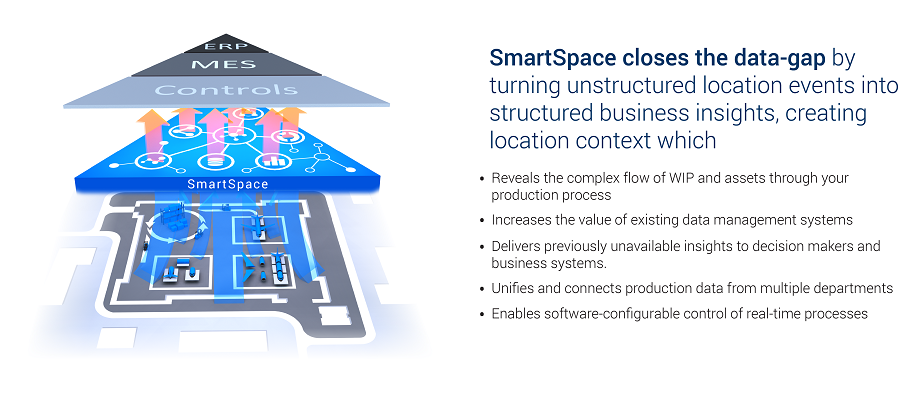

Ubisense SmartSpace closes that data gap by keeping track of the location, movement, interaction and status of all critical hangar assets. By keeping business systems constantly appraised of deviations from plan, those systems are better able to get things back on track. In any process with moving parts, the motion and interaction of those parts (tools, WIP, materials etc.) is the critical indicator of how things are going.

Once the location of all those parts are known it is possible to monitor the related processes and start to improve your overall business efficiency in your MRO environment.

Stay tuned for more blogs in this series by signing-up below.

Do you want to learn more on How to Improve Business Efficiency in an Aerospace MRO Environment? Watch Dr Hugh Revie’s On-Demand Webinar on the same topic: WATCH NOW

Written by Dr Hugh Revie, Sales Director Aerospace EMEA at Ubisense

Hugh is one of the world’s leading experts in the Aerospace industry. Hugh has now been working in Aerospace for more than 30 years and, prior to joining Ubisense, started his career in aviation after graduating with a doctorate in Engineering and, initially working for British Aerospace. Around 18 years ago, he created his own company, CoreData Limited, focused on helping airlines, MROs, OEMS and aircraft supply chain companies with solutions that could drive value from the large amounts of data they were accumulating. He finally sold the company to Rolls Royce. Since then he has been working with customers to improve efficiencies by using their own data and continues to do this with Ubisense.