INDUSTRIES

Commercial Vehicles

Ubisense helps manufacturers of commercial, construction and agricultural vehicles transform operations. Seamlessly connecting the location and movement of tools, parts and products in real-time to better orchestrate processes, saving time, improving efficiency and reducing cost.

Control Quality. Save Time. Lower Costs.

Ubisense understands the two main drivers of cost in commercial vehicle assembly: time and quality.

Reducing assembly time increases throughput and maximizes the utilization of valuable manufacturing resources. Improving quality by eliminating errors reduces expensive repair and rework processes. Ubisense location sensing technology digitizes all the manual and moving parts of the assembly process to help you improve quality and save time.

Solutions for Commercial & Agricultural Vehicle Manufacturing

Tool Management

Locate and manage tools and equipment across large production facilities.

Yard Management

Locate and manage Work-In-Progress (WIP) in real-time across indoor and outdoor areas.

Production Logistics

Add real-time location data to logistics management to optimize efficiency.

Find & Prioritize Products in the Yard

With high volumes of finished and unfinished product widely dispersed around site, it can be difficult to find and stage assets effectively. Time is often wasted searching for lost or forgotten Work-in-Progress (WIP).

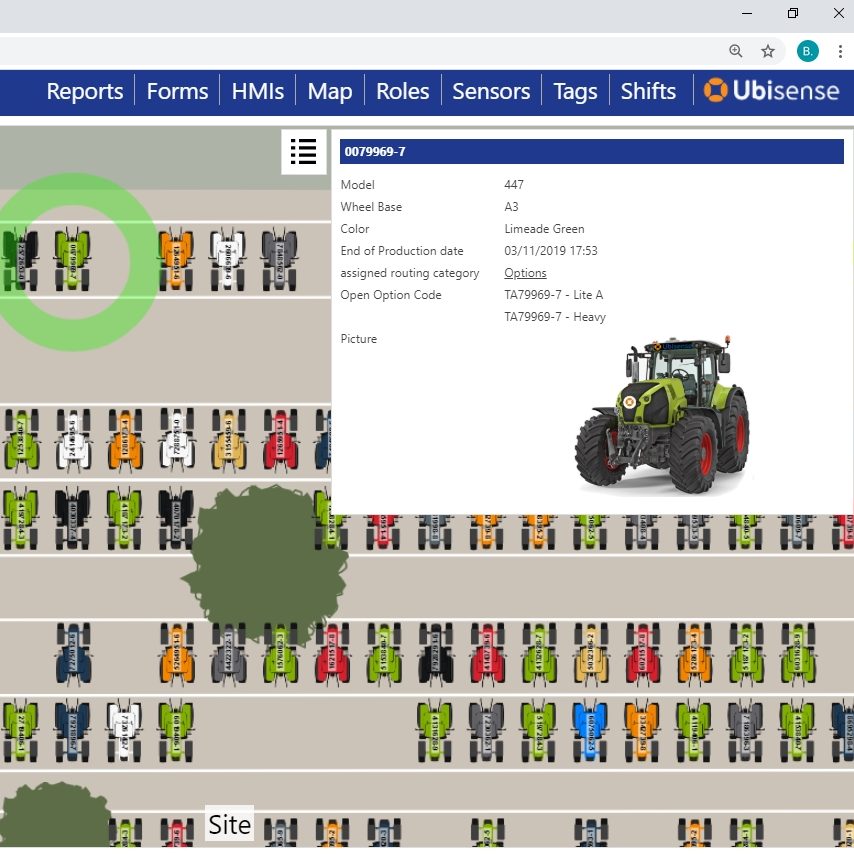

Ubisense Yard Management reduces wasted search time and helps coordinate the correct staging of WIP in your processes.

- Quickly find finished or unfinished products on a digital map of your facility

- Create searches based on product location and status

- Easily see the real-time location and status of all WIP

Locate & Manage Assembly Tools

Manufacturing complex vehicles involves many manual and interconnected processes, requiring the availability of the right tools and equipment, in the right place at the right time. Often tools are staged incorrectly or not returned to storage areas, putting them at risk of being lost or damaged.

Ubisense Tool Management knows the location and status of all of your tools, all of the time, reducing wasted search time and helping coordinate the correct staging of equipment.

- Quickly find tools on a digital map of your facility with simple and configurable searches

- Create alerts for tools or equipment due (or overdue) maintenance but still in use

- Automate and error-proof the check-in/check-out procedure for tools to streamline operations and protect against Foreign Object Damage (FOD)

Ubisense Process Interlock

Ubisense Process Interlock uses an Ultra-Wideband (UWB) real-time location system and SmartSpace software to reduce risks and prevent product damage during assembly operations.

- Avoid costly damage to products and equipment

- Keep workers safe with real-time alerts

- Control the advancement of production

Ubisense Process Verification

Combining precise and reliable ultra-wideband tracking with traditional RFID and scanning technology, Ubisense Process Verification can error-proof critical assembly operations, improve quality and reduce rework.

- Ensure the correct identification of critical parts, products, and material

- Automatically validate tasks are completed to specification

- Reduce costly warranty claims and improve efficiency

You’re in good company

Ubisense Success Story

“CLAAS offers an extremely wide choice of vehicle models in order to meet the needs of modern agriculture. By adding Ubisense technology to the facility at Le Mans, we will be able to best cope with product complexity while reducing waste.”

Aldric Pavec, Production Manager, CLAAS

Location Data Integration

Ubisense solutions are not limited by location technology type. As well as using our high-performance, Ultra-Wideband (UWB) Dimension4™ Real-Time Location Systems (RTLS), Ubisense can use any other location sensing technology to offer extended use cases across the plant.

Bluetooth Low-Energy (BLE), Wi-Fi or RFID can be easily integrated in the same system for high volume parts and materials tracking to optimize production logistics, optical vision and laser systems add millimetre accuracy for critical fastening and tightening sequences, and GPS extends coverage outside to storage and test areas.

Application Integration

Ubisense connects to any existing system of record, including ERP and Manufacturing Execution Systems (MES) to update with real-time events and activity, and automate the recording of operations to reduce errors and improve quality.

Extensible APIs support any non-typical integration through various interfacing technologies including REST services, .NET, and direct RDBMS integration.

Reporting and Dashboard

Build and customize process and KPI reports from large volumes of historical and real-time data. Move from out-of-date paper and spreadsheet planning documents to real-time systems, offering insight and optimization of highly variable processes.

Highlight process inefficiencies and give decision makers valuable business insights into performance, trends and previously hidden processes.

How the system works

Locate Tools & Products

Dimension4 ultra-wideband sensors track the real-time location and movement of assets such as cordless tools, assembly equipment and Work-in-Progress (WIP) through production facilities.

Engineered to cope with busy and dynamic commercial vehicle factories, Dimension4 sensors are resistant to location errors caused by highly reflective and metallic environments.

Define Workspaces & Processes

Our solutions are based on the powerful, sensor agnostic SmartSpace® enterprise platform, which uses location data of assets and a digital, 3-dimensional model of the environment to create a real-time digital twin of your physical operations.

Define precise work zones and track the movement of products through defined process steps, alerting for unwanted deviations, and use configurable reports to identify bottlenecks and areas for improvement.

How to get started

Speak to one of our commercial vehicle experts today to explore the various solutions location technology can support and define the sensor and tag coverage required for your facility.

Technology Leadership

World-class technology specifically designed to operate in complex and dynamic commercial vehicle plants with a proven track record of reducing costs and increasing efficiencies.

Deep Expertise

Trusted advisers with deep understanding of digitizing assembly processes from long-standing relationships with leading global manufacturers.

Proven Solutions

Strong customer references demonstrating compelling return on investments and a global service network meaning local support where and when you need it.

Zero Interruption

A solution architected with commercial vehicle manufacturers in mind, with the ability to install, configure, test and deploy without disruption to ongoing operations.

Ubisense Unveils Dual UWB and RTK-GPS Technology for Enhanced Outdoor Asset Tracking Systems

Ubisense Appoints Felix Buehner as New Chief Revenue Officer

Ubisense Appoints Felix Buehner as New Chief Revenue Officer

Ubisense, a leader

HEAD OFFICE (UK)

Ubisense Limited

St Andrew’s House

St Andrew’s Road

Chesterton

Cambridge, CB4 1DL

United Kingdom

+44 1223 53 5170

NORTH AMERICA

Ubisense America LLC

1630 Welton Street, Suite 1000E

Denver, CO 80202

United States

+1 720 549 7553

EUROPE

Ubisense GmbH

Klaus-Bungert-Straße 5B

40468 Düsseldorf

Germany

+49 211 2297330

Ubisense SAS

52 Boulevard De Sébastopol

75003 Paris

France

+33 1 83 79 06 82