Gone in 60 seconds – thinking beyond the fixed workstation

Ever since Ransom Olds introduced the automotive assembly line in 1901, and Henry Ford the moving conveyor in 1913 we’ve pretty much been building cars the same way: cramming processes into fixed workstations. The fixed workstation is a very simple concept. Step 1: define the takt-time based on planned production volume, typically around 60 seconds for high volume. Step 2: set the line speed and workstation size to create 60s workstations. Step 3:

On-Demand Webinar: Why IoT Won’t Revolutionize the Manual Assembly Line

On-demand Webinar Why IoT Won't Revolutionize the Manual Assembly Line The Internet of Things is potentially revolutionary for many industries but will it revolutionize manual assembly? In this presentation Adrian Jennings argues that the overwhelming majority of manual workflow in the assembly plant means that OEMs will need to look beyond IoT for full digital process connectivity. Mr. Jennings will describe how to augment IoT to reach those manual processes

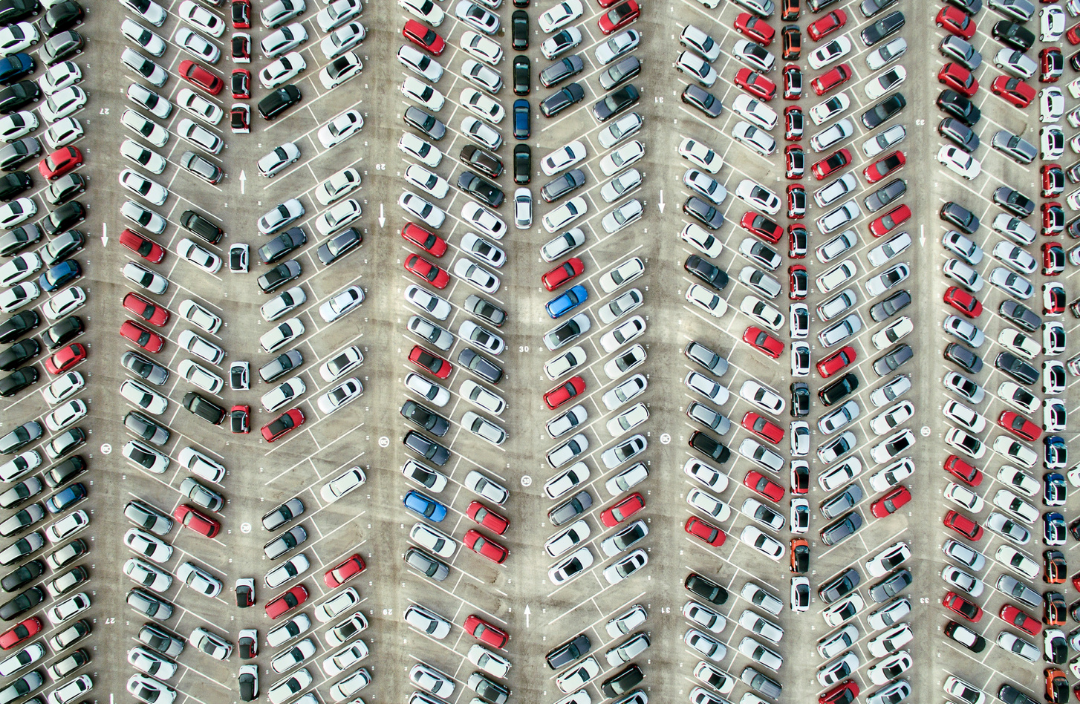

On-Demand Webinar: How to locate and manage products in the yard

On-demand Webinar How to locate and manage products in the yard With high volumes of finished and unfinished product widely dispersed around site, it can be difficult to find and manage assets effectively In this webinar, Hubert Peyre, Business Development Manager at Ubisense will cover: Eliminate wasted search time by pinpointing assets on live site maps Meet delivery schedules by setting alerts for misplaced, forgotten or aging assets Create graphical reports to gain

On-demand Webinar: A guide to digital problem solving in automotive factories

On-demand Webinar A guide to digital problem solving in automotive factories If approached incorrectly, plant-digitization can be a daunting task that might never get started. However, when adopting best practices learned over the last decade, digitization becomes the painless outcome of a connected set of digital problem-solving steps. In this 60-minute webinar, Adrian Jennings of Ubisense provides unique insight into the critical elements of factory digitization best practice. Key topics

Ubisense and MRO Drone launch world’s first ‘Smart Hangar’ solution

Ubisense and MRO Drone launch world’s first ‘Smart Hangar’ solution Smart Hangar delivers efficiency and productivity in the MRO lifecycle Ubisense Group plc (AIM:UBI),a global leader in enterprise intelligence solutions, is today announcing a partnership with pioneers of autonomy and creators of innovative aviation software products, MRO Drone, to offer the world’s first ‘Smart Hangar’ solution, combining automated aircraft inspection with automated tool and asset management to improve efficiency and increase

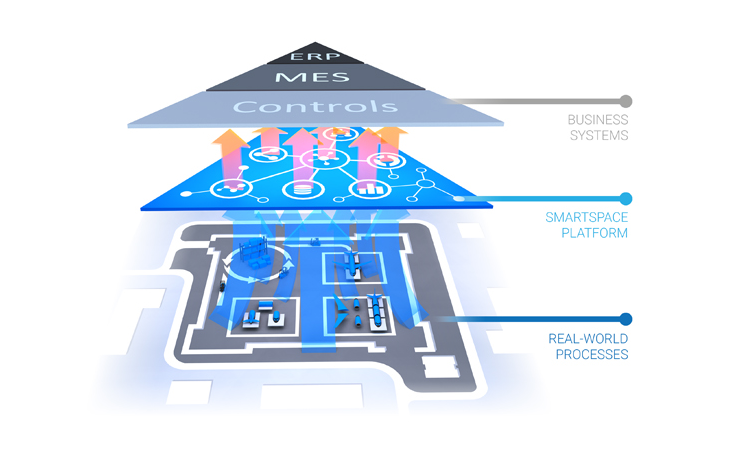

Ubisense rolls out SmartSpace platform across multiple plants for leading luxury automotive manufacturer

Ubisense rolls out SmartSpace platform across multiple plants for leading luxury automotive manufacturer Ubisense Group plc (AIM:UBI), a global leader in enterprise location intelligence solutions, is supporting Daimler by rolling out its SmartSpace IIoT platform at production sites across the globe. SmartSpace is an important enabling component of the manufacturer’s ‘Paperless Factory’ initiative, which is helping the business to increase productivity, quality, and flexibility through real-time control of