From zero-code to contact-tracing in under a week

Have you ever wondered where all these contact-tracing and social-distancing solutions came from? It’s not like they were developed and ready to roll out – the use of technology to support back-to-work strategies is unprecedented in history. Unprecedented and unpredicted: up until March we’d barely thought about shutting down; up until April we’d never considered what it would mean to open back up, and here we are in May with a veritable smorgasbord

On-Demand Webinar – How to save your Aerospace MRO Facility $1m per annum per bay

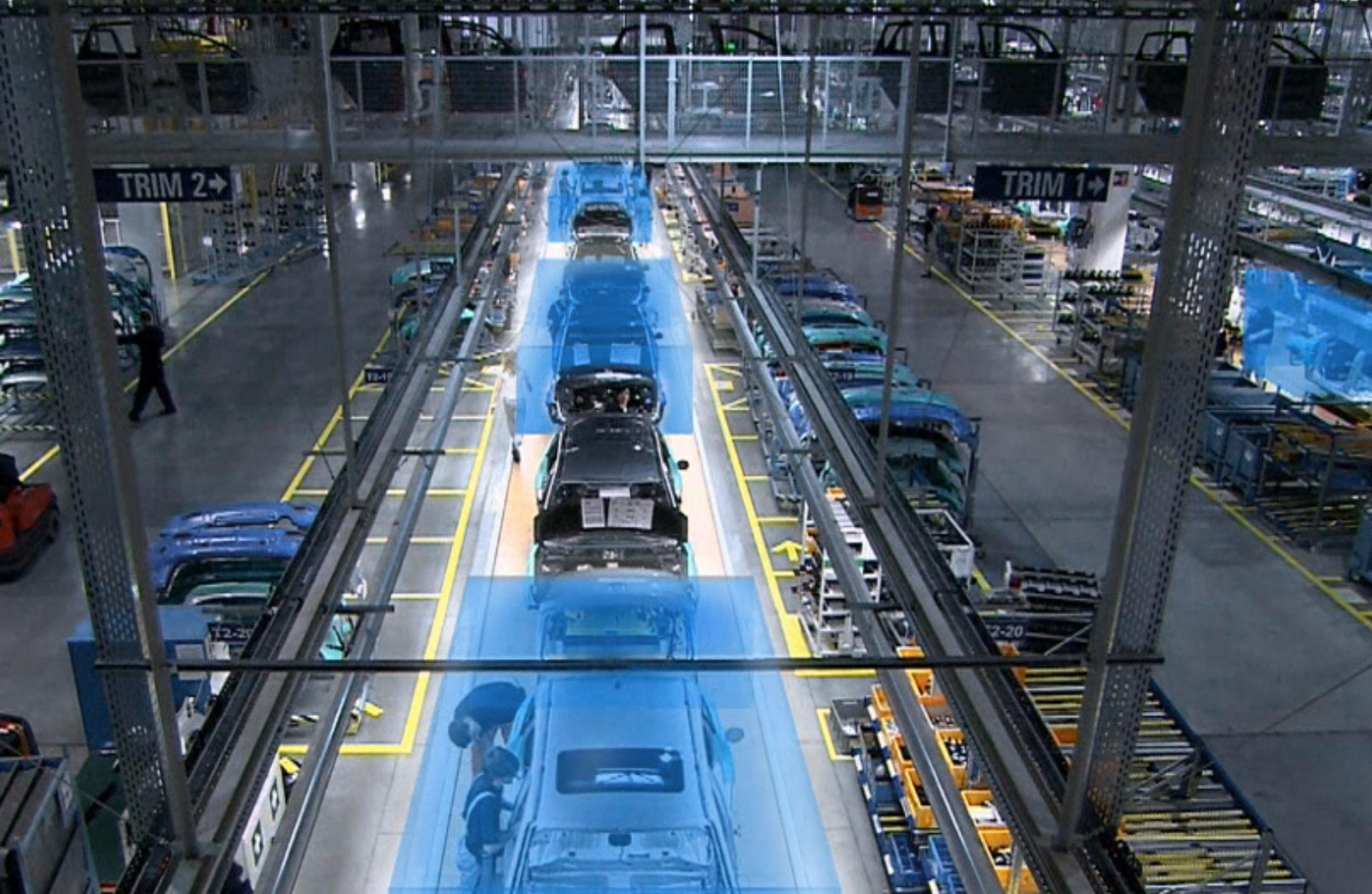

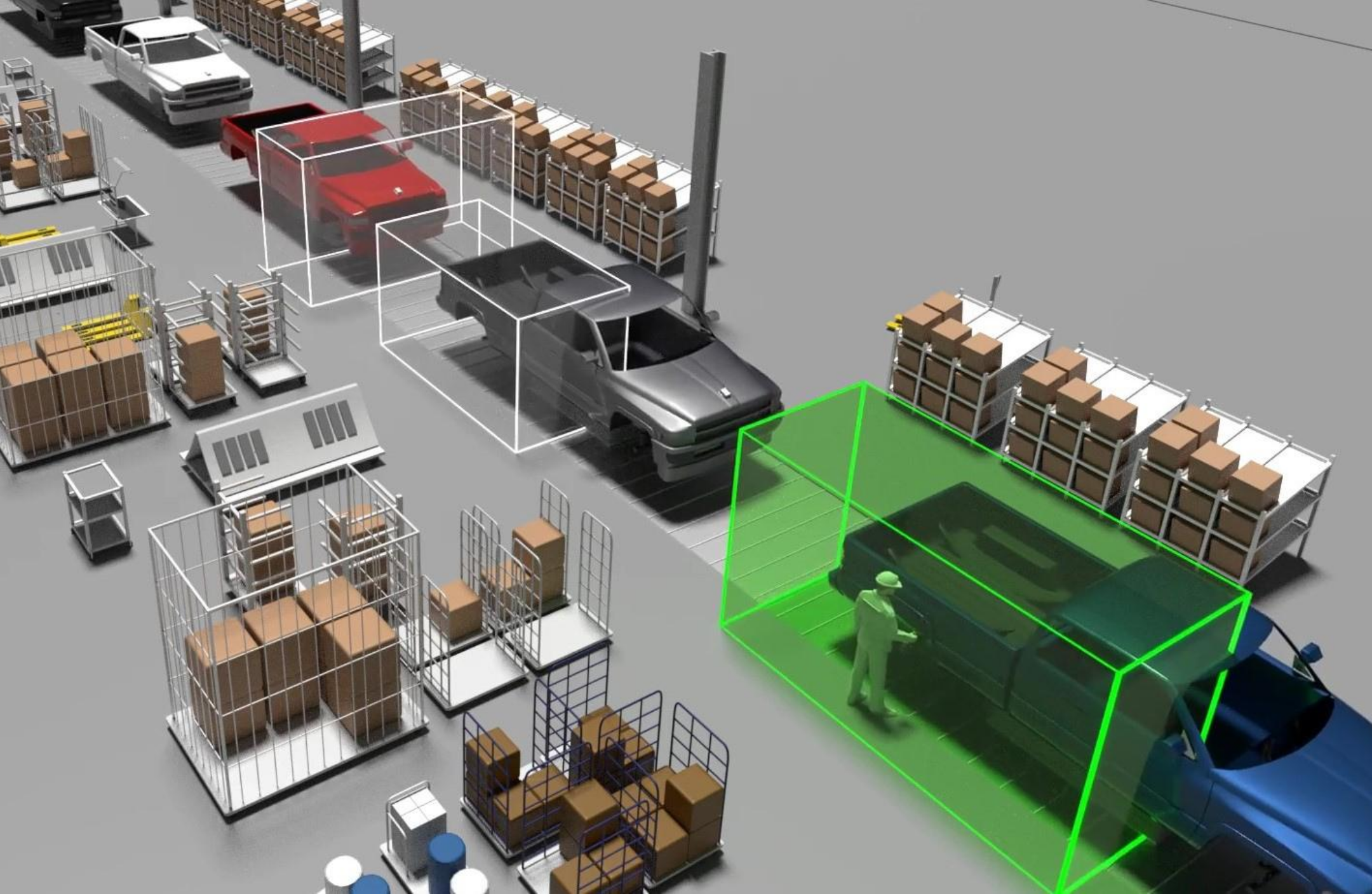

Who is Ubisense? Ubisense transforms physical spaces into smart spaces, bringing manufacturers proven gains in quality, cost, and productivity. Our SmartSpace® platform monitors the physical flow of the factory creating a real-time “digital twin” of the process. This Digital Process Twin provides the deep situational awareness that empowers people to make more insightful decisions, and business systems to operate with foresight and certainty. With offices in the UK, France, Germany,

Don’t Judge a Tracking Technology by its Cover

Don’t judge a book by its cover we are told, but I’ll admit that I’ve bought more than one volume based on its cover art. Those books haven’t always provided a life-changing literary experience, but what the heck? It was only a $10 gamble. An investment in location intelligence to underpin a process digitization strategy is somewhat more than a $10 proposition and selecting the right tracking technology deserves more thought than a

On-Demand Webinar: Lessons from restarting an automotive plant safely

On-demand Webinar Lessons from restarting an automotive plant safely As businesses restart operations, the focus is on maintaining social distancing. But at what cost to efficiency and productivity? Learn how organizations can not only use location technology to help workers maintain safe distances, but also protect operations from future shut-downs and find new ways to be efficient. In this webinar, Adrian Jennings, Chief Product Advocate at Ubisense will discuss: The two primary

On-Demand Webinar: Location Intelligence Across the Automotive Plant

On-demand Webinar Location Intelligence Across the Automotive Plant Location intelligence solutions have been in high demand recently as manufacturers get back to work by monitoring worker movement and enabling contact tracing. However, for over a decade the primary purpose of these solutions has been to maximize throughput and reduce errors through digitization. In this webinar, Adrian Jennings, Chief Product Advocate at Ubisense will discuss: The most commonly deployed use-cases (from torque sequence

It’s about time automotive manufacturers replace a 70-year-old technology

The barcode was first imagined in 1948 by Joseph Woodland, inspired by the dots and dashes of Morse code. Woodland was responding to a challenge set by a local retailer in Philadelphia, looking to find ways to speed up the process of checking-out in stores. By the 1960’s, an engineer, David Collins revived this idea and, combined with the availability of lasers, was putting thick and thin striped lines on railway cars so