Guide for Selecting the Right Asset Tracking Technology

Asset tracking enables the capture of real-time data about the location, movement, and status of assets. This information can provide valuable insights into processes and workflows, increasing productivity and efficiency.

However, choosing the right asset-tracking technology can be daunting.

With options ranging from UWB to GPS to the ubiquitous RFID, how do you know which one is right for your business? Asset tracking technologies overlap in capabilities, and there is no one-size-fits-all solution. Furthermore, sometimes two complementary technologies are needed to track an asset. And then there’s the software side to worry about.

Issues like real-world performance, accuracy, reliability, compliance and integration with existing infrastructure add to the complexity of selecting the right asset-tracking technology.

The journey starts with understanding your business requirements. While every business is different, there are some key questions all businesses should answer to help identify the right technology.

1. What Types of Asset are you Tracking?

Modern asset-tracking technologies can track all kinds of assets. Work in Progress (WIP), inventory, machines, tools, and even processes – everything is trackable.

So how do you decide what to track?

Expensive assets are worth tracking. High-accuracy tracking technologies like GPS and UWB are used to track commercial vehicles & machinery to prevent theft, yard management, and other location challenges.

However, the cost of an asset is merely one aspect to consider when selecting the type of asset to track.

Operationally critical assets are also excellent candidates for tracking. These are assets that may not be expensive but are essential to the operation of your business. Tools are a good example. Tools are relatively inexpensive. However, misplaced or incorrectly calibrated tools can cause production delays and faulty outputs.

Modern asset-tracking technologies do not stop at tracking assets. They can also track processes and the interaction between assets. Tracking interaction between assets can be used for enforcing policies, compliance, provisioning equipment, virtual fencing, supply chain management, and more.

It would help if you thought big when choosing what to track.

2. What is your Tracking Environment?

Tracking tags communicate with the tracking system via radio signals. Unfortunately, radio signals are prone to interference and attenuation. Therefore, you should choose the tracking technology as per the tracking environment.

The tracking environment can be broadly divided into indoor and outdoor environments.

Indoor tracking environments like a factory floor have machines, racks, walls, chemicals, water, and people. A typical indoor environment can;

- Absorb the radio signal from the tracking tags, thus making it difficult for the receiver to receive location data.

- Bounce the radio signal from the tracking tags. This creates “radio echoes” (multipath interference) and may cause the sensor to record the incorrect location data.

Indoor environments probably also have other radio transmitters. External radio frequency interference (RFI) from devices like two-way radios, remote controls, motors, relays, motion sensors, and other tags can interfere with location tag transmitters and sensors.

Outdoor environments also have their challenges. The radio signal from the tracking tags can be scattered and absorbed by buildings, trees, haze, fog, and rain.

Outdoor asset tracking systems may also encounter extreme weather conditions and a wide range of temperatures.

Outdoor asset tracking hardware must be rugged and weatherproof to withstand the elements. They should also be able to operate at extreme temperatures and over a wide range of temperature variations.

Tracking processes that move between indoor and outdoor environments presents an additional challenge. Ubisense’s dual-mode devices, like UWB + GPS, come in handy when tags move between indoor and outdoor environments.

Dual-mode devices can seamlessly switch between indoor and outdoor tracking modes without user intervention. The device automatically uses the most appropriate technology for the tracking environment.

A Note on Real-World Performance

Just like the advertised mileage of a car, the performance of an asset-tracking system in the real world may be lower than what was measured in a lab under ideal conditions.

The real world is a dynamic environment. It is full of metallic objects, moving people & equipment, and interference. The tracking system should be able to handle all of these challenges and still provide accurate location data.

With Ubisense, you can locate with confidence. Using Time Distance of Arrival and Angle of Arrival with advanced filtering algorithms, Ubisense gives you more reliable and accurate location data.

Accuracy is not the only performance metric where real-world performance may be lower than promised. Some other points to keep in mind when selecting asset-tracking technology are.

- Reliability

- Flexibility and Scalability

- The density of tracked assets

- Flexibility

- Battery life

3. What level of accuracy do you require?

Asset tracking technologies can be very accurate. For example, Ubisense’s ultra-wideband (UWB) tags have an accuracy of 30cm. You need this level for accuracy if you need to track assets for, say, collision avoidance.

However, not all use cases need this level of accuracy. The accuracy of asset tracking technology ranges from “centimeter-level accuracy” to “room-level accuracy.”

Room-level accuracy (2-5 meters) may be sufficient for tracking a forklift. However, tracking a tool may require shelf-level accuracy. If shelf-level accuracy is required, 3D coordinates are typically needed necessitating the use of UWB technology.

While tag technology defines the upper limit of accuracy, sensors and software also have a role to play.

Ubisense’s DIMENSION4™ UWB Real-Time Location System (RTLS) sensors measure Time-Difference-of-Arrival (TDoA) and 2-axis Angle-of-Arrival (AoA) of UWB signals at the same time to provide accurate 3D tracking.

DIMENSION4™ also uses advanced filtering algorithms. The algorithm selects the most reliable measurements, thus improving precision by rejecting obstructed and reflected signals.

4. Are you restricted by cost?

The cost of the asset tracking technology is also an important consideration. While both BLE and UHF Passive RFID have similar accuracies, BLE tags are 100x more expensive than RFID tags. Therefore, a cost vs. benefit analysis should be performed when selecting an asset-tracking technology.

5. What Form Factor do you require?

The form factor of the tracking tag is also an important consideration. The size and shape of the tag become important for smaller objects and tools. For example, BLE tags are bigger than RFID tags and, therefore, unsuitable for tagging small objects.

Ubisense offers a variety of tag designs, from hard-wearing and robust industrial tags suitable for heavy machinery or products to lightweight tags that can be attached to safety equipment or clothing.

Ubisense also offers modular tags. These tags can be easily integrated into third-party equipment. Modular tags draw power from the host and are pre-certified to minimize additional RF testing.

6. Will you require Integration?

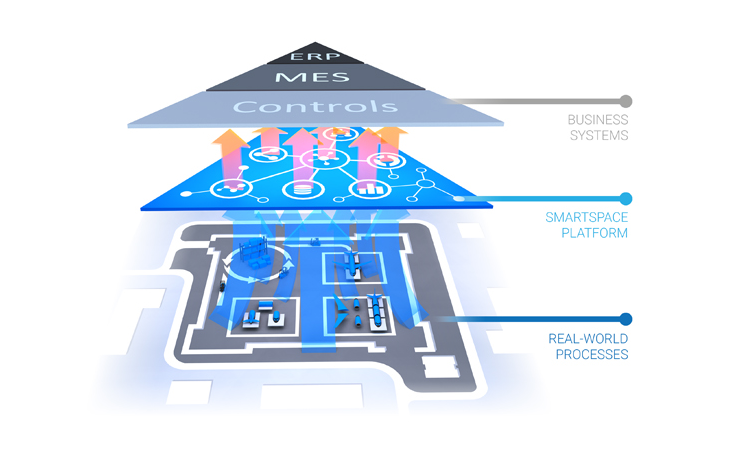

State-of-the-art asset tracking technology goes beyond tracking the spatial location of assets by integrating them with other systems and processes.

Digital twins, IIoT, automatic digital audit, and integration with ERP are some features to look for in an asset-tracking technology stack.

Ubisense has taken asset tracking to millimeter-level accuracy by integrating UWB tags with a camera-based vision system. This asset-tracking technology can precisely locate assembly tools to within millimeters and distinguish between adjacent fasteners. This “bolt-level” accuracy is state-of-the-art in asset tracking.

7. Can you afford weaker battery life?

While passive technologies like passive RFID don’t require a battery, active technologies such as BLE and UWB do. As a result, the battery life of the tags is an essential consideration for active tags.

Ubisense UHF active RFID tags have a battery life of fewer than three years, while batteries on our UWB tags can last more than ten years. Ubisense industrial tags have a deep-sleep mode to preserve the battery. Replacing batteries on inferior tracking technologies can be a costly process.

8. Is Dual Mode Operation beneficial to your operation?

Another critical feature to consider is dual-mode operation. Dual-mode asset tracking tags can simultaneously use one or more location tracking technology. Dual mode capability is vital if you need to track assets in different environments or at different accuracy levels along the process.

Ubisense provides asset tracking technologies in various dual-mode combinations – like the UWB + BLE dual-mode tag. This tag leverages the strengths of both technologies.

The Bluetooth Low Energy (BLE) part of the tag is a low-power consumption system. One of the many use cases of BLE is the passive identification of other devices within range. The Ultra Wideband (UWB) localization feature uses wideband ranging to detect even small changes in location and movement direction with precision. Dual mode tags are used for creating smart, situationally aware assets.

9. Have you considered the Tracking Frequency?

The tracking frequency is the number of times per second that the asset tracking system updates the location of an asset. The higher the tracking frequency, the more accurate the system will be.

Ubisense’s predictive Real-Time Location Systems (RTLS) have a tracking frequency of hundreds of hertz.

What is Asset Tracking Software?

Asset tracking software is a powerful tool that businesses across various industries can use to track and manage their physical assets, including products, machines, vehicles and even people. Tracking software can provide businesses with real-time data that helps them optimize operations, prevent loss, and reduce costs.

Ubisense’s SmartSpace asset tracking system uses a combination of hardware and software to provide businesses with accurate, real-time location data for their assets. The system uses a variety of sensors that are placed around a facility or site, and tags that are attached to the trackable assets. The sensors detect the tags and transmit their location data to the software application. The data is then processed and displayed on a series of reports and customizable maps of the site.

Industrial applications

The Ubisense location tracking system is used in a variety of industries, including manufacturing, automotive, logistics, and healthcare. In manufacturing, the system can be used to track the location of tools, materials, and work-in-progress items. This allows manufacturers to optimize their operations and reduce downtime by ensuring that the right tools and materials are available when they are needed.

In logistics, the Ubisense location tracking system can be used to track the location of shipping containers, trucks, and other assets. This helps logistics companies optimize their routes and delivery schedules, and provides them with real-time information about the location of their assets.

In healthcare, the system can be used to track the location of medical equipment, such as hospital beds, wheelchairs, and infusion pumps. This helps healthcare providers ensure that equipment is available when it is needed, and can also help prevent the loss or theft of valuable medical equipment.

What makes SmartSpace different?

One of the key benefits of the SmartSpace system is its accuracy. SmartSpace can track assets to within a few centimetres, which makes it much more accurate than other asset tracking systems, especially those that rely on GPS, Bluetooth, or RFID technology. This level of accuracy makes SmartSpace ideal for tracking assets in indoor environments, where GPS signals may be weak and inaccurate. It also allows for functionalities requiring greater accuracy, such as tool control operations on auto production lines and automated parking features in transit depots.

Another benefit of the Ubisense location tracking system is its ease of use. The system is designed to be user-friendly, with a simple interface that allows users to quickly and easily view the location of their assets. This makes it perfect for businesses looking to implement a system and begin tracking their assets right away.

In addition to its accuracy and ease of use, the Ubisense location tracking system also provides businesses with a range of other useful features. For example, the system can be used to set up geofences—virtual boundaries that trigger alerts when assets move outside of them. This can be useful for businesses that need to ensure that assets stay within a certain area, such as a construction site or warehouse.

The system can also be used to track asset usage, which can help businesses optimize their operations and reduce costs. For example, by tracking the usage of tools or equipment, businesses can identify opportunities to optimize their maintenance schedules, or to reduce the number of tools or equipment that they need to purchase.

Overall, the SmartSpace location tracking system contains powerful asset tracking software that can provide businesses with real-time data about the location and usage of their assets. Whether it is used in manufacturing, auto production, transit hubs, logistics, or healthcare, the system can help businesses optimize their operations, prevent loss, and reduce costs. With its accuracy, ease of use, and range of useful features, the Ubisense location tracking system is an excellent choice for any business looking to make spaces “smart”.

The Benefits of Asset Tracking

Some use cases of real-time tracking include;

These are just some of the many benefits of asset tracking. Real-time tracking is being used across industries to improve operational processes.

Production Optimization

Asset tracking can be a key component in production optimization. By understanding where assets are and how they are being used, businesses can improve their production processes. In some cases, asset tracking can even prevent costly errors.

Let’s explore how asset tracking can help optimize production.

- WIP limits are a key factor in reducing cycle times. Asset tracking helps ensure that these limits are adhered to. By tracking assets throughout the production process, it is possible to identify bottlenecks and areas where production is being delayed. This information can then be used to make adjustments to the production process in order to improve efficiency and reduce cycle time.

- Overall Equipment Effectiveness (OEE) is the gold standard for measuring manufacturing productivity. Asset tracking can help improve the three crucial OEE factors – availability, performance, and quality.

In today’s competitive marketplace, companies are always looking for ways to optimize production and increase efficiency. Asset tracking can play a role in nearly every facet of production optimization, from reducing WIP to improving OEE. By tracking the location and status of assets, companies can identify potential problems before they become serious.

Quality

Quality control is an important part of any production process, as it helps to ensure that products meet the standards set by the company or customer.

Asset tracking can help to ensure quality by providing a way to track the movement of materials and parts through the production process. This information can be used to identify and correct problems that might occur during production.

Take Ubisense’s computer-vision-enabled sequence control solution for example.

This solution for assembly processes allows hand-held assembly devices to automatically identify products or parts of products being worked on even down to the bolt level. The solution then determines the required tightening sequence and automatically enables the tool. This error-proofs the operation.

Efficiency

Asset tracking can help improve efficiency in different business functions like production, customer service, and supply chain management. Asset tracking makes production more efficient. While asset tracking can benefit operations of all sizes, it is a game-changer for complex manufacturing processes.

Industries where the processes are complex and sites are vast, it is too easy to lose track of assets and tools. Resources not being in the right place at the right time, lead to costly delays. By keeping tabs on resources, asset tracking helps ensure that they are available when and where they are needed. Asset tracking solutions not only track asset coordinates, but also provide a high level of control to ensure that uncontrolled or incorrect tools are not used inside specified workspaces.

Compliance

Manufacturing compliance is the set of requirements, regulations and practices that manufacturers must follow.

There are compliance risks associated with every stage of production, assembly, or Maintenance Repair and Overhaul (MRO) processes. Asset tracking can help to mitigate those risks by providing accurate and up-to-date records of where assets, and tools are, who is using them and for what purpose.

In the event of an audit, asset tracking records can be used to automatically and quickly identify any non-compliant practices.

Asset tracking makes compliance and audit simpler and gives more control to quality and compliance teams. It also makes internal audits faster and cheaper.

Error-proofing

There are many sources of error in manufacturing processes. The most common are human errors, machine errors, and material errors.

Errors lead to off-spec production which must be reworked – increasing the cost of production. Not only do errors increase production cost, they also have a ripple into other areas of the business like customer service, asset downtime, and regulatory compliance.

Asset tracking is making it easier for industries to identify opportunities to reduce errors and improve overall efficiency. By understanding where assets are and what condition they are in, companies can more easily make changes that will reduce errors.

Additionally, asset tracking allows for greater visibility into the movement of assets, helping to prevent losses and better manage resources.

A major concern in the Industry 4.0 ecosystem is the role of human operators and workers as a source of error.

No system can completely stamp out the risk of human error. However an asset tracking system can help make those errors visible quickly.

For example, by tracking machines needed on a production line, workers can get that machine in place in advance, preventing unplanned downtime. By tracking pallets that are moved to the wrong loading dock, site managers can know before an item is shipped in the wrong direction. Or, by tracking perishable goods, workers can know well in advance that the asset needs to be moved, refrigerated, etc. to avoid expiration.

Safety

According to the National Safety Council, the cost of workplace injuries in 2020 was $163.9 billion. In the same year, the manufacturing sector saw 300 preventable fatal injuries – the six highest among all sectors.

Workplace injuries not only have a high human cost, but they also hurt manufacturers in other ways. For example, when a machine is involved in a serious accident, it will remain down for a week or more, which can slow production.

Asset tracking can improve operational safety by providing workers with information about their surroundings in real-time. This helps to prevent accidents by warning workers of unsafe spaces and disabling equipment when it gets too close to people.

Asset tracking also plays a crucial role in helping with employee mustering. By tracking the location of employees in real-time, companies can ensure that everyone is accounted for in the event of an emergency. This can help reduce the amount of time needed to gather everyone together and can also help keep track of who has evacuated and who is still inside the building. Asset tracking also helps first responders to respond more effectively.

Cost

One of the biggest benefits of asset tracking is that it allows for more efficient resource allocation. With accurate data on all assets and their locations, departments can easily find and use the equipment they need without double-booking or going over budget. In addition, if an asset is misplaced or lost, it can be quickly located and recovered using the tracking system. This reduces the amount of wasted time and money, making asset tracking a valuable tool for businesses of all sizes.

The effective tracking of movable assets can also lead to cost savings through extending the usable life of those assets. By having accurate records of when an asset was last serviced, maintenance can be planned and scheduled to avoid costly repairs or replacements. Furthermore, regular servicing and maintenance will help ensure that assets are running at peak performance, resulting in less down time and improved overall productivity.

Locating Missing Assets & Theft Prevention

Losing track of tools, materials, and inventory can be costly for a business. Not only does it lead to lost productivity, but it also opens the door for theft.

An asset tracking system can help businesses keep track of their assets and tools, as well as reduce the chances of theft.

Traditional systems like using markers, spreadsheets, stand-alone software, and handheld scanners are not very good at locating missing assets or preventing theft. They are also very time-consuming, and add to the cost of production.

A cloud-based asset tracking system can assist organizations in keeping track of their tools, assets, WIP, and inventory materials as precisely as needed.

Automation

[e.g. Automate tool audits. e.g. Overtaking the crane drive to prevent collision.]

Different industries can achieve different levels of automation, with some being easier to automate than others. For example, in a chip manufacturing plant, automation can be increased relatively easily, while in discrete manufacturing, there are limits to automation.

Production processes like auto assembly depend on human dexterity. But does this mean discrete manufacturing cannot be automated?

While it is difficult to automate discrete manufacturing tasks, the location, flow, and sequencing of these tasks can be automated with the help of asset tracking. The use of asset tracking to automate discrete manufacturing is limited only by imagination.

For example factories are using asset tags to track and manage inventory. This helps to ensure production lines have the correct inventory on hand, and that items are not misplaced or lost. Asset tracking is also being used to monitor production processes and identify issues and bottlenecks to improve production efficiency. However, this is not all. Asset tracking has expanded beyond production line automation to include safety automation, audit & compliance automation, and more.

Maintenance

Asset tracking plays a key role in digitizing maintenance processes and workflows.

By automatically gathering asset data and integrating it with maintenance management software, asset tracking can help industries automate and streamline their asset maintenance processes.

Predictive maintenance is one of the most promising applications of asset tracking data. By analyzing asset data, asset tracking can help organizations detect potential issues and schedule maintenance before problems occur.

Transit Yard Management

Transit Yard Management and asset tracking go hand in hand.

Transit Yard Management systems can track the precise real-time location and movement of vehicles across both indoor and outdoor areas using Ultra-Wideband (UWB) and GPS technology.

- Knowing the precise location of vehicles helps

- Reduce vehicle search time

- Lower dispatch and scheduling errors

- Reduce shuffle time

- Respond quickly and easily to changing situations such as breakdowns and inclement weather

Better Insights

Asset tracking systems can provide businesses with valuable insights into their processes.

Asset tracking systems map the physical flow of a factory into a real-time “digital twin”. This allows businesses to have a better understanding of process performance and areas of improvement. A “digital twin” makes the complex processes of the physical world “visible” and controllable.

Moving objects make up between 60% to 80% of processes in manufacturing and MRO. Asset tracking systems can monitor these complex moving processes. The data collected can be used to control and optimize the processes in line with the plan.

Asset tracking systems can be integrated with ERP and MES planning systems to keep them up-to-date with real-time location data. Real-time data in ERP and MES helps save time, reduce errors and give real-time insights into business performance.

Integration

Asset tracking systems can integrate with other business systems. Integration has many benefits including improved inventory management, reduced costs, improved asset utilization, and better planning.

Asset tracking systems can be integrated with a variety of business systems including

- ERP systems

- MES systems

- Warehouse Management Systems (WMS)

- Computerized Maintenance Management Systems (CMMS)

Asset tracking plays a key role in improving the efficiency and effectiveness of many business processes. By automating asset data collection and integration with other business systems, asset tracking can help businesses automate and streamline their processes. In short, asset tracking provides benefits that can help businesses save time and improve their bottom line.

Conclusion

When selecting the right asset-tracking technology for your business, it is essential to consider multiple factors.

The operating environment, cost of the technology, battery life, form factor, and tracking frequency are all important considerations.

Ubisense has a wide range of experience designing and deploying state-of-the-art asset-tracking solutions. We can advise you on the best technology or combination of technologies to suit your requirements. Contact us today to learn more.