I’m pretty certain when Sting penned those lyrics back in 1980 he wasn’t imagining a manufacturing plant in 2020. Yet, here we are needing to rethink the way we work to ensure adequate social distancing to keep operating safely.

Real-Time Location Systems (RTLS) that track the interaction of people certainly has a role to play. With a long history of successfully tracking the location and movement of things, we take this stuff pretty seriously. Here’s my take on the top 4 things to consider based on conversations we’re having with our many, diverse clients.

1. Low Tech Vs High Tech

I read with interest that manufacturing plants are returning to work with physical barriers in place. It serves a purpose – and workers will be thankful for feeling protected – but practically, unless those barriers are 2m wide or permanent in structure, their efficacy may be questionable. Not to speak of long-term effects on motivation and productivity spending shift after shift without seeing another human being.

There are of course more high-tech solutions; a tag carried by people or attached to equipment relaying its precise location to sensor base stations throughout the environment. Those locations are then tracked in software in real-time, giving alerts if people come within 2m of each other (through sound, light, haptic feedback, or a combination) to indicate potential risk.

This has the advantage of alerting people in the moment without needing physical walls, but can also monitor interactions over time. This gives rise to a whole host of data and analytics, storing encounters to produce accumulated employee risk profiles. Low-tech may not teach us much, but high-tech gives us a data trail that can be leveraged to model improved processes on the factory floor from tracking movement and interactions; ‘what if we do it this way…’.

But of course, it doesn’t prevent contact, it just monitors it. A combination of high tech tracking should be considered with a package of more low-tech protocols (mask wearing, temperature checking, limiting communal areas and shift sizes) and evaluated over time – which of course tracking data comes in mightily useful for.

2. Accuracy is nothing without reliability

Two metres sounds like a big margin when tracking the proximity of two people. But if the RTLS can only locate each person to within 1 metre, the same reading could either mean a safe distance, or not.

It’s therefore tempting to focus on system accuracy. A lot of RTLS claims incredible levels of accuracy. In lab conditions. The problem of course is that most of us don’t work in labs.

We’re used to people asking us for hyper-accurate location data, and our response is almost always the same; accuracy only matters if it’s reliable. You can certainly have centimetre accuracy, but when your factory is filled with highly reflective metal objects (as most are), you need a system that can cope with those noisy environments to get the high-confidence location data needed.

Always evaluate RTLS on reliability, not just accuracy. That way you can ensure contact tracing data that is uncontaminated by the false positives inherent in less reliable systems.

3. It’s not just about standing close

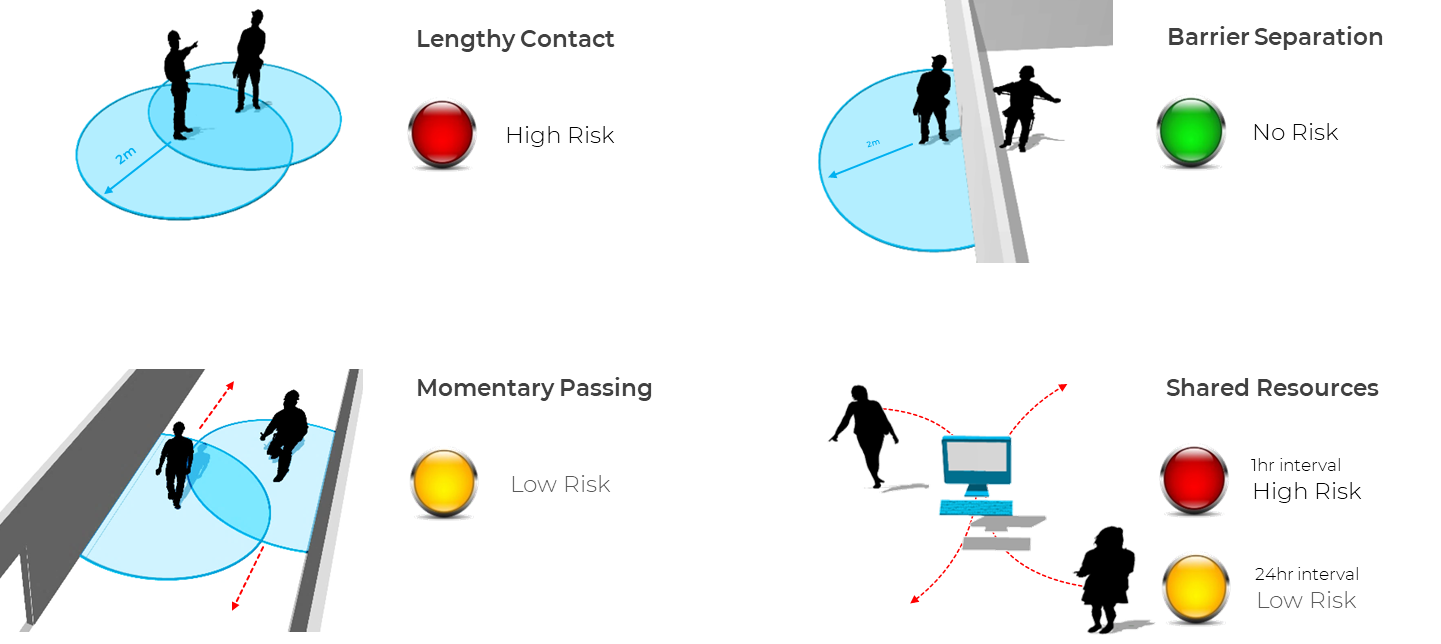

Technology that measures the proximity of two devices gives some short-term benefit, no doubt. But the transmission of contagions is much more nuanced than that. A simple 2 metre distance doesn’t take account of the physical environment, length of time of contact, or the use of shared equipment causing people-object-people transmission. For example, a tool passing from one person to another could be an issue. Tracking that same tool being passed via a cleaning station or passed after a significant amount of time could be less of an issue.

Each situation carries a different level of risk and if tracked correctly, provides valuable intelligence over time to keep workers safe and optimise operations. Take a look at the examples below;

When the location and interactions of people and objects are defined and measured in software, not hardwired into proximity sensors, the contagion model can be quickly adapted as transmission mechanisms become better understood over time.

4. Long-term opportunity masquerading as a short-term problem

Fortunately for a lot of our customers (and other companies already using RTLS), they already have the necessary sensor infrastructure to receive highly accurate, highly reliable location data. For them, contact tracing is just a simple software update.

But what if you don’t have the infrastructure already? Well, for sure it requires some short-term investment. But once you have the systems in place, imagine what else you can achieve with the same data.

The benefits of location systems already enjoyed by many companies suddenly open up (optimised manual process flows, control of assembly systems, searching for lost or forgotten tools or work-in-progress). Not only are you able to accelerate return-to-work now, but also accelerate the digitisation of your manual process flows in the future.

Conclusion

So there you have it. Less about ‘Don’t stand so close’, and more about ‘don’t stand so close for so long’, ‘who did you stand so close to’ and ‘who used that tool last and was it returned for cleaning’.

Not as catchy and unlikely to get in the top ten, but certainly more useful to help your business return-to-work safely and, who knows, possibly be better positioned to increase productivity and quality in the future too. If you’d like to contact Ubisense to talk to us about contact tracing, please email me – just don’t call into the office because I’m not there. Stay safe.

Written by Steven Manifold, Chief Marketing Officer at Ubisense

Steven Manifold is Chief Marketing Officer of Ubisense. Twenty years of marketing experience at both the bluest of blue chips and high growth SaaS companies has taught him that people value one thing; frictionless engagement with companies. If you want to know more about Ubisense, the markets we operate in or the challenges we can solve, just email him directly: [email protected]