A Differentiated Approach to Deployment – How Ubisense Accelerates Rollout With LiDAR Enabled Planning, Calibration, and Validation

Deploying a Real Time Location System (RTLS) across a complex production environment is often the slowest and most uncertain stage of any transformation project. Traditional methods rely heavily on manual measurement, time and effort, and assumptions about how radio signals will behave once the system goes live. It is an approach that consumes valuable time and resources while still leaving uncertainty about how well the system will perform under real operating conditions.

Ubisense has taken a fundamentally different approach. By combining LiDAR based survey technology, 3D simulation tools, and patent pending calibration methods, the company helps customers plan, deploy, and validate their RTLS with unprecedented speed and confidence. Every stage of the rollout, from the first site scan to final performance verification, is built on empirical data rather than estimates.

Capture with speed and certainty

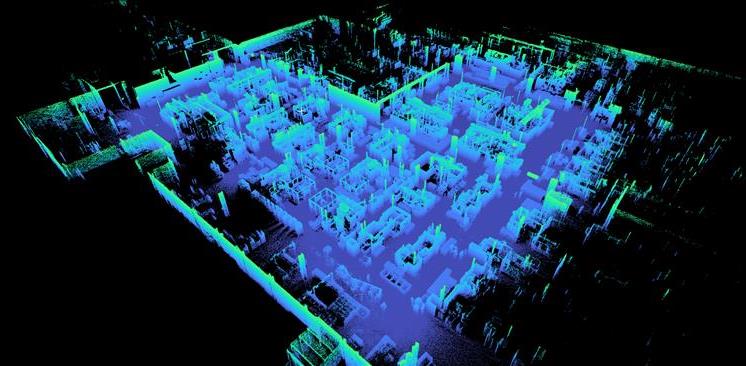

At the start of every new prospective project, Ubisense engineers conduct a LiDAR based site capture. Using handheld SLAM (Simultaneous Localization and Mapping) scanners, they record a precise 3D model of the environment, including the physical structures, surfaces, and potential sources of signal reflection or obstruction. What once took several days of manual surveying, and was largely based on experience and intuition, is completed in a matter of hours, producing a point cloud that accurately represents the site's geometry and forms the empirical basis for automated planning and simulation.

Figure 1: Point cloud image of a manufacturing facility taken from SLAM LiDAR

This process does more than just accelerate deployment; it removes ambiguity. Because the LiDAR data captures real world structure at high fidelity, the engineering team can model sensor performance and line of sight behaviour across the entire space before a single sensor is installed.

Planning with precision

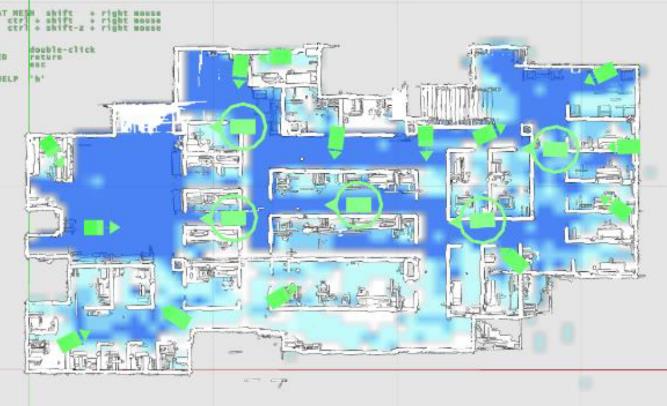

From the 3D model, Ubisense's system planning tools automatically generate a digital twin of the customer's environment. The software runs simulation models that replicate how Ultra-Wideband (UWB) signals will behave within that space, identifying the strongest positions for sensor placement and forecasting the level of accuracy that can be achieved in each zone. Crucially, the system can simulate multiple scenarios to stress test: what if the object is fast moving? Placed at a low height? Tagged at a high update rate versus low?

Figure 2: Simulation of expected coverage (blue) with a tag worn at height of 0.5m (left) and 1.4m (right) for a personnel safety use case

This step transforms the deployment process from reactive to predictive. Instead of placing sensors, testing coverage, and adjusting later, Ubisense customers start with a data driven layout that has already been performance tested virtually. It ensures every installation delivers the expected fidelity from day one.

Calibration through innovation

Once the infrastructure is installed, Ubisense applies its patent pending auto calibration technology, which fuses real UWB tracking data with ground truth LiDAR trajectories. The LiDAR scan provides absolute spatial reference points, allowing the system to automatically align its coordinate frame and fine tune sensor synchronization without manual intervention.

This capability represents a step change in how large RTLS networks are brought online. In traditional deployments, engineers must manually calibrate each anchor, introducing small inconsistencies that compound as the system scales. Ubisense's approach reduces that process to a repeatable, automated workflow, significantly shortening setup time while improving spatial accuracy.

Validation grounded in evidence

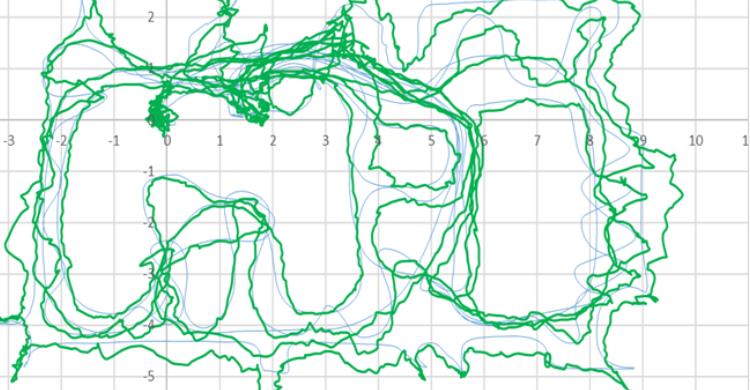

LiDAR data continues to add value once the system is operational. After installation, Ubisense uses a secondary, independent LiDAR reference to validate system performance, comparing every tracked position generated by the RTLS against the known ground truth trajectory. This provides empirical evidence that the deployed system meets its accuracy and coverage targets across the full facility.

This capability is unique in the market. While most vendors can only offer theoretical or sample-based validation, Ubisense delivers proof verified by measurable ground truth. It allows all customers to deploy with confidence and document performance to the same standard required for safety critical manufacturing and aerospace operations.

Figure 3: Ground truth path (blue) and the superimposed Ubisense 4-sensor UWB system path (green) in a challenging manufacturing environment

Transforming deployment from a challenge into a strength

By combining LiDAR capture, automated simulation, and data driven calibration, Ubisense has redefined what deployment speed and assurance look like in industrial RTLS projects. Customers benefit from faster rollout times, higher system accuracy, and repeatable, validated outcomes across multiple sites.

Ubisense does not just make RTLS deployment quicker; it makes it provable. Through LiDAR enabled precision, the company delivers systems that perform exactly as planned, with full visibility of how and why.

That is what it means to transform physical space into SmartSpace®.

To see how this approach can accelerate your next RTLS project, and find out how SmartSpace can improve your operations, contact Ubisense here, or enquire directly below:

Oscar Harwood

Junior Account Executive

[email protected]

+44 1223 785812