Navigational Menu

Intro

The following pages are intended to be an information hub for John Deere employees to locate resources to assist them in understanding, supporting and maintaining Ubisense solutions.

Ubisense & John Deere History

The first Ubisense deployment with John Deere was in 2012 at the Des Moines Works on the Cotton production line and is still in operation today. Since this time, John Deere has deployed 1,000’s of sensors across its Des Moines Works, Harvester Works, Dubuque Works, Waterloo Works and Davenport Works factories.

Solutions

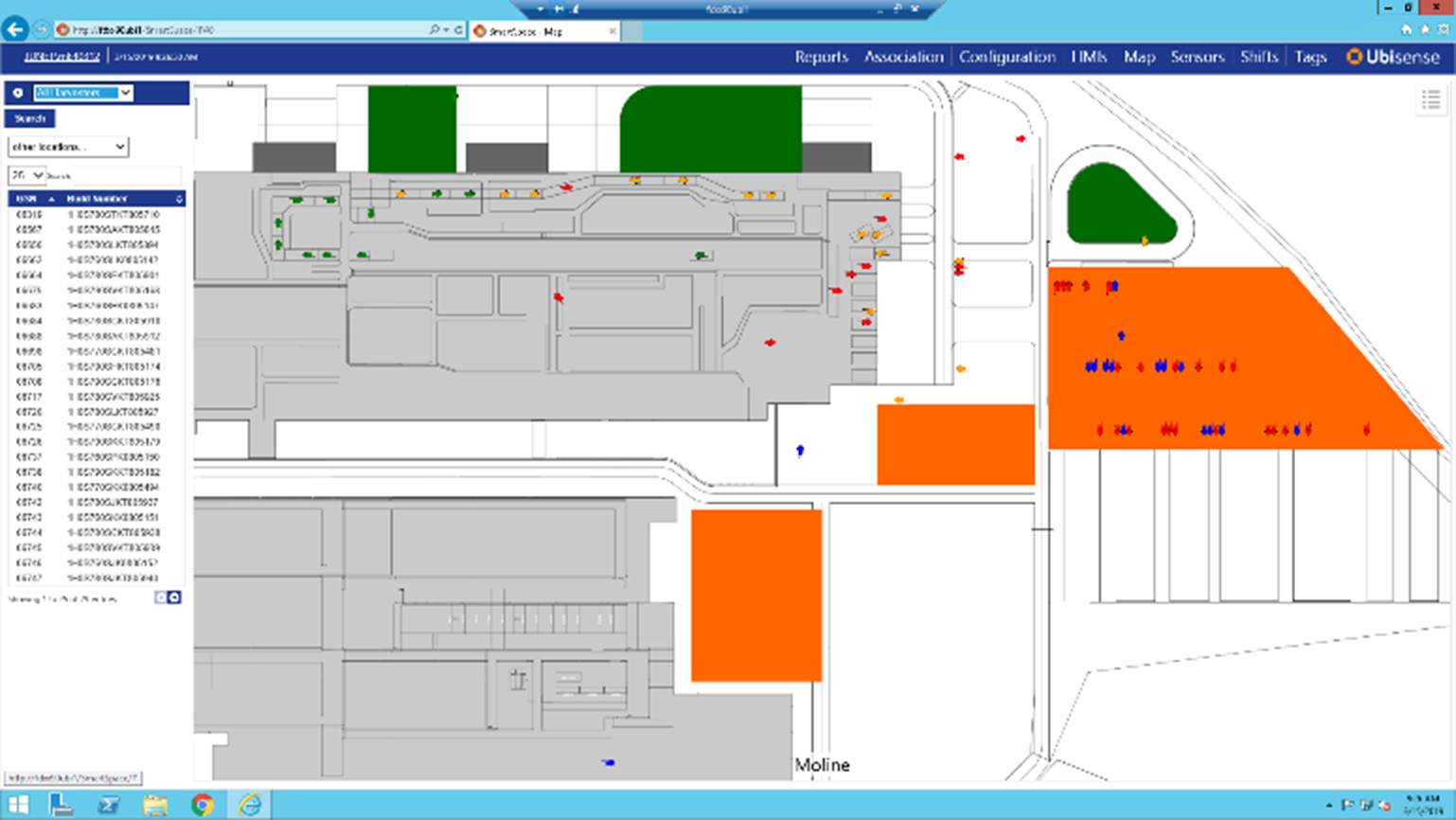

Visibility

Product

- Real-time web map for locating products or additional tracked assets or tooling.

- Customizable graphical representations for quickly identifying model variants.

Deployed at Des Moines Works, Harvester Works, and Davenport Works

Deployed at Des Moines Works, Harvester Works, and Davenport Works

Visibility

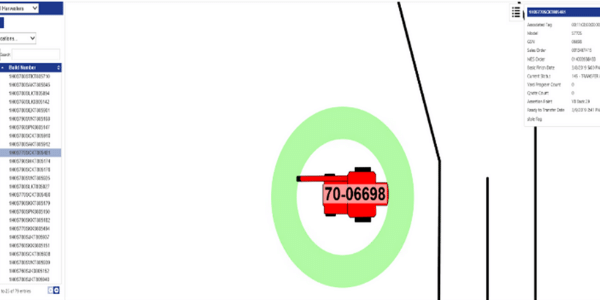

Product Search

- Search for

- All products

- Product GSN

- Sales Order

- MES Order

- Model

- Area

- Qnotes

- Yard/Repair Programs

Process Monitoring & Alerts

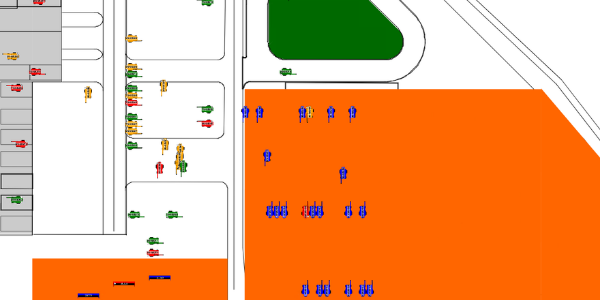

Product Completion State

- Green – More than 1 day prior to Basic Finish Date

- Yellow – Within 24 hours of Basic Finish Date

- Red – Past Basic Finish Date

- Blue – Product in ‘Warehoused’ status

Deployed at Des Moines Works, Harvester Works, and Davenport Works

Deployed at Des Moines Works, Harvester Works, and Davenport Works

Process Monitoring & Alerts

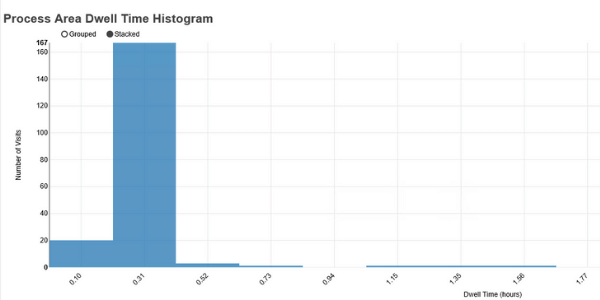

Product Time Monitoring

- Dwell time will be recorded against individual areas and will only be accrued when the shift assigned to that area is active

- Over occupancy monitoring

Process Monitoring & Alerts

Product Time Monitoring

- Dwell time will be recorded against individual areas and will only be accrued when the shift assigned to that area is active

- Over occupancy monitoring

Deployed at Des Moines Works

Process Monitoring & Alerts

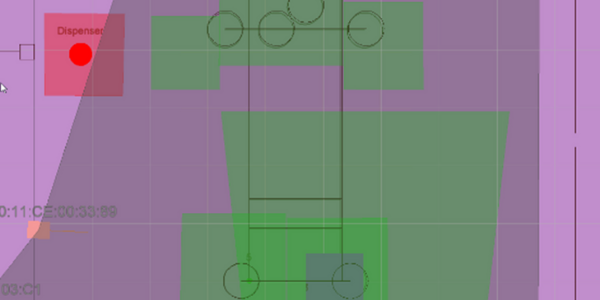

Fluid Fill Monitoring

- Tracks & monitors fluid fill applicators in 3D entering fill points

- Records applicator entering fill area and sends OPC tag to PLC

Process Monitoring & Alerts

Combine Clear Path Monitor

- SmartSpace monitors the assembly line for production equipment that is not out of the way of a Combines path to progress down the line. When the tracked equipment moves to its home position and out of the assembly area, a OPC tag is sent to JDAAT. JDAAT monitors and processes all inputs to assert the Combine path is clear and can proceed to the next station.

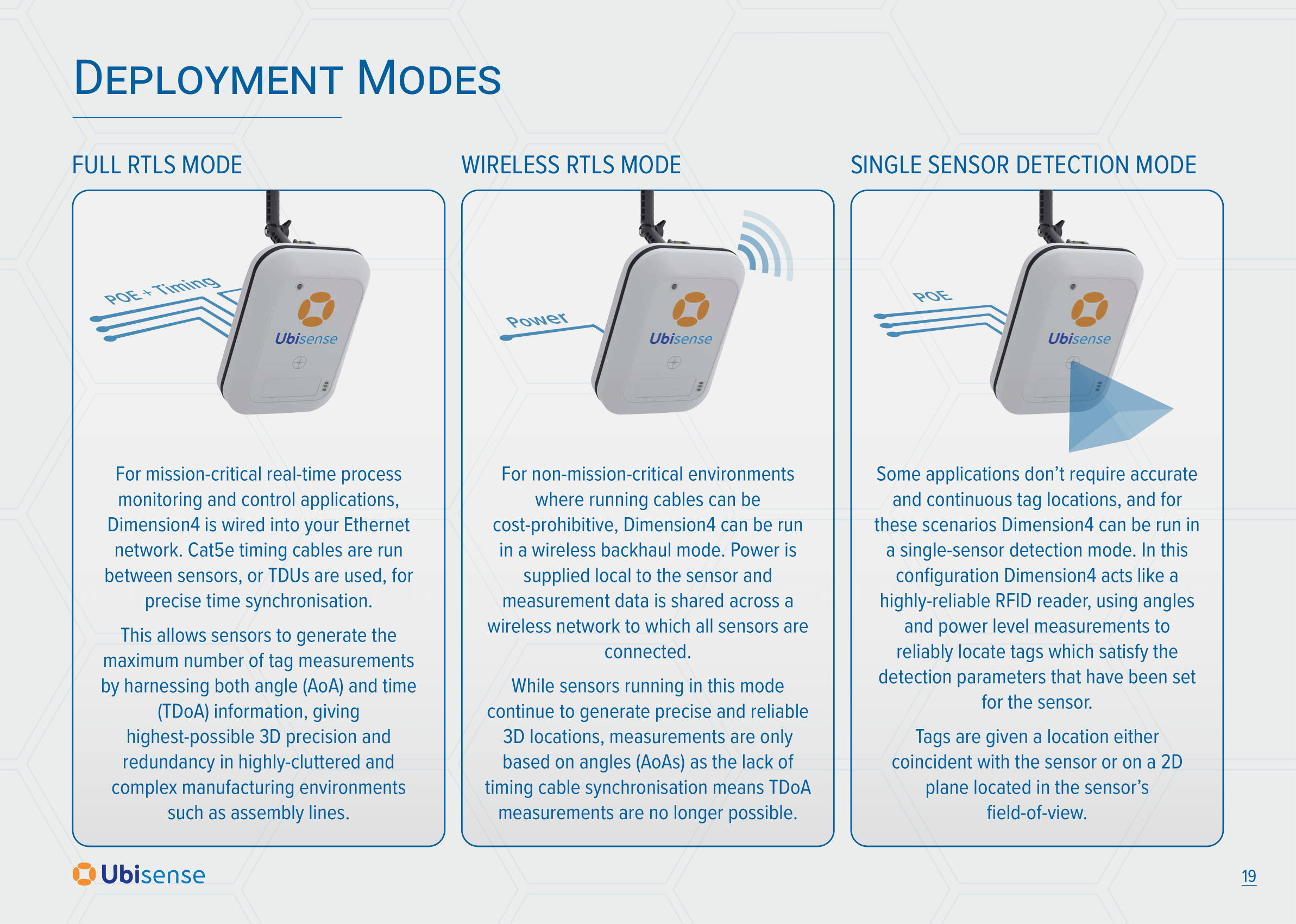

Dimension4

DIMENSION4™ is the result of decades of experience delivering industrial-scale, real-world solutions that pin-point the true 3D location, movement and identity of people and things in critical processes.

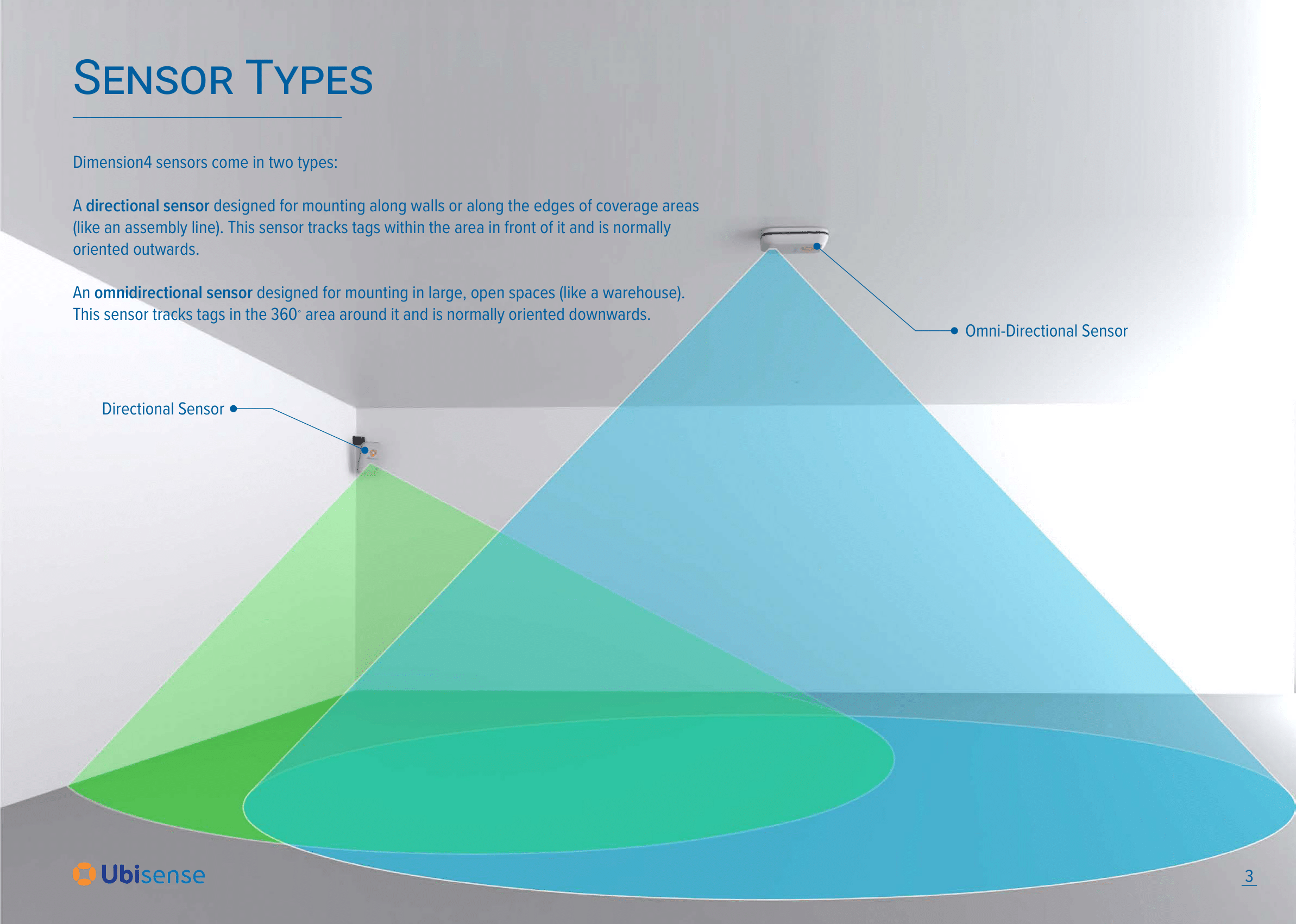

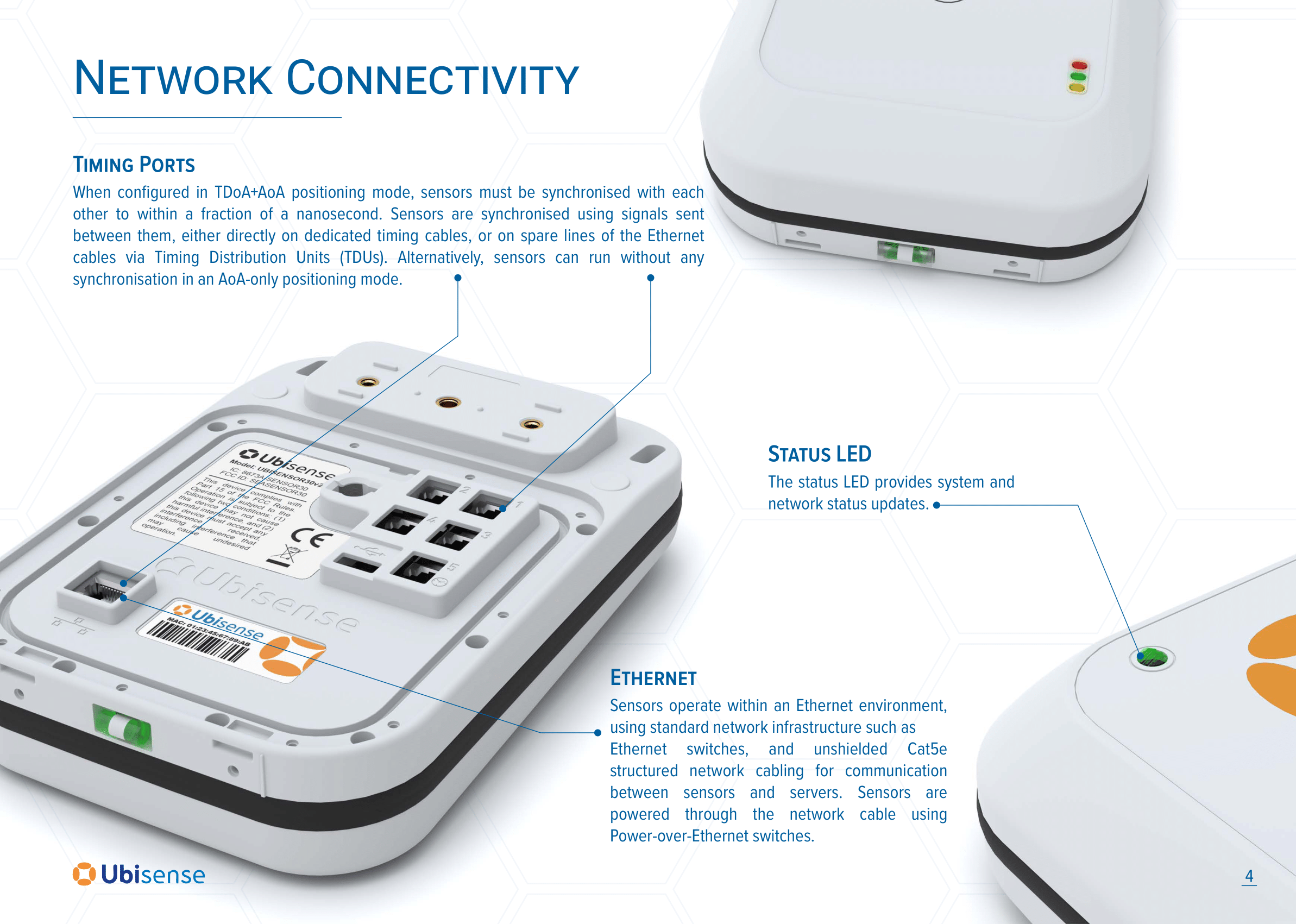

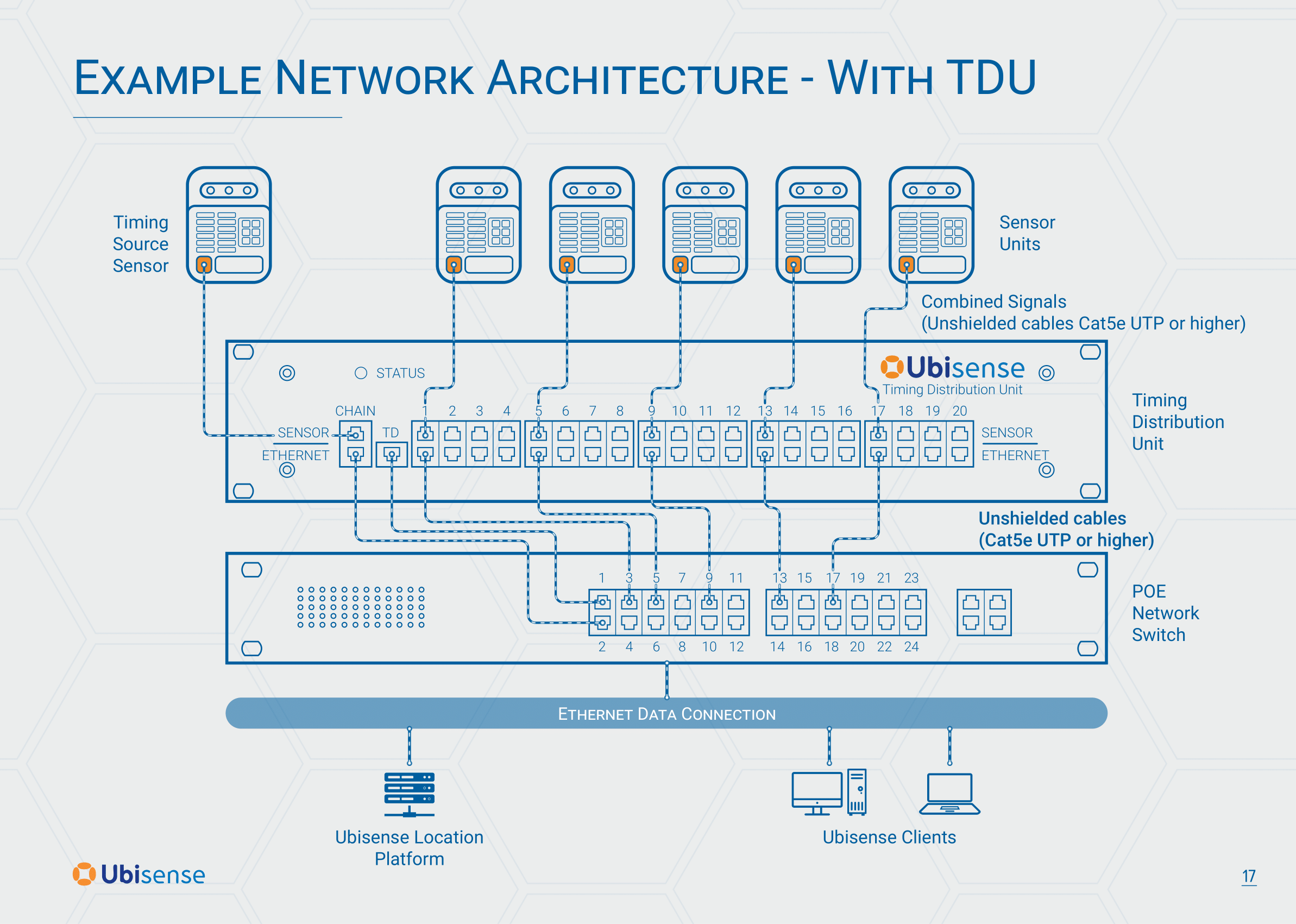

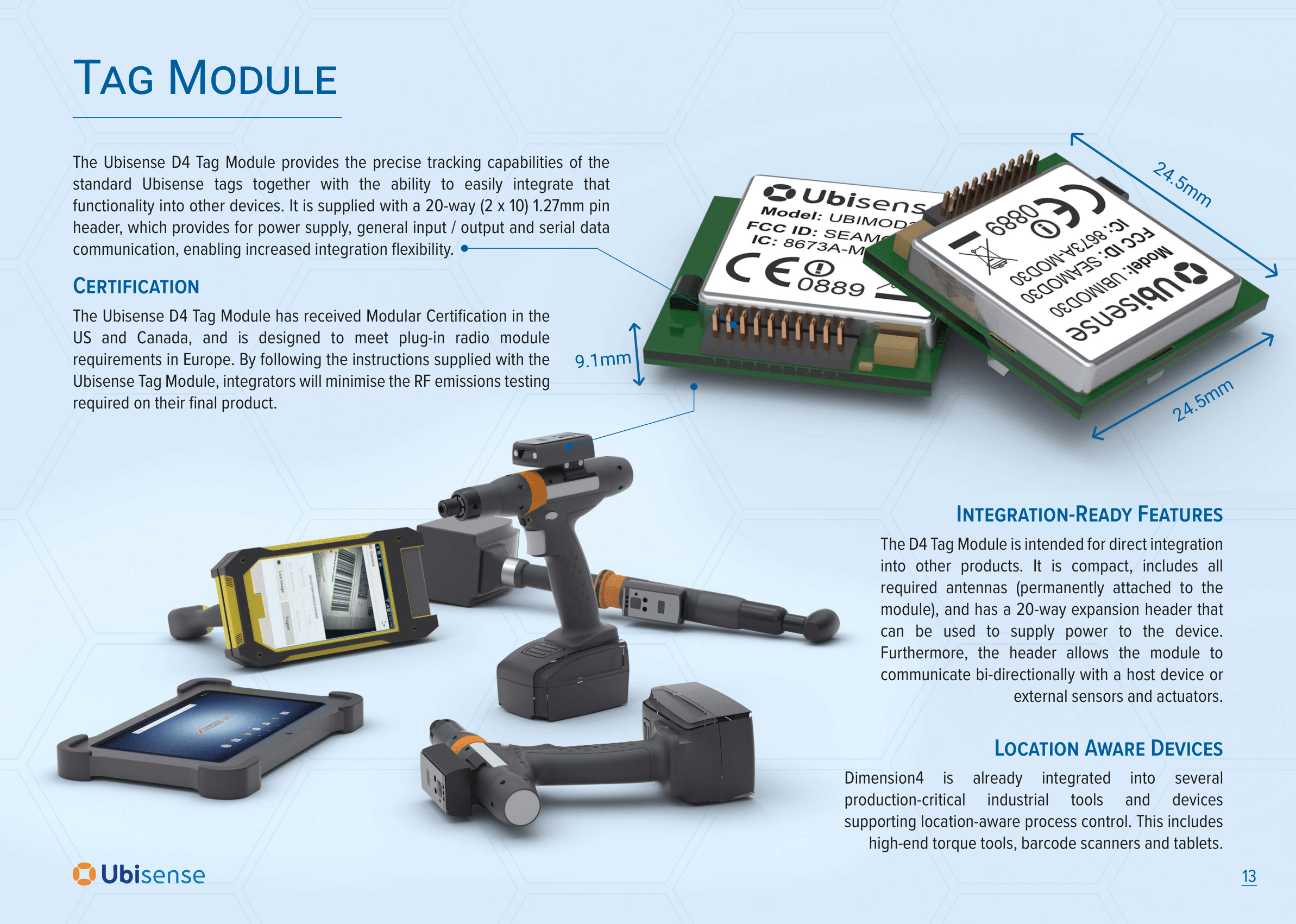

Sensors

OVERVIEW

The Ubisense DIMENSION4 range of ultra-wideband (UWB) sensors are precision measurement devices, containing an array of antennas and UWB radio receivers. The sensors detect UWB pulses from Ubisense DIMENSION4 Tags, allowing the Ubisense location system to find the tag positions to a very high accuracy in three dimensions, in real-time.