On demand webinar – Looking after us at work: where in the warehouse?

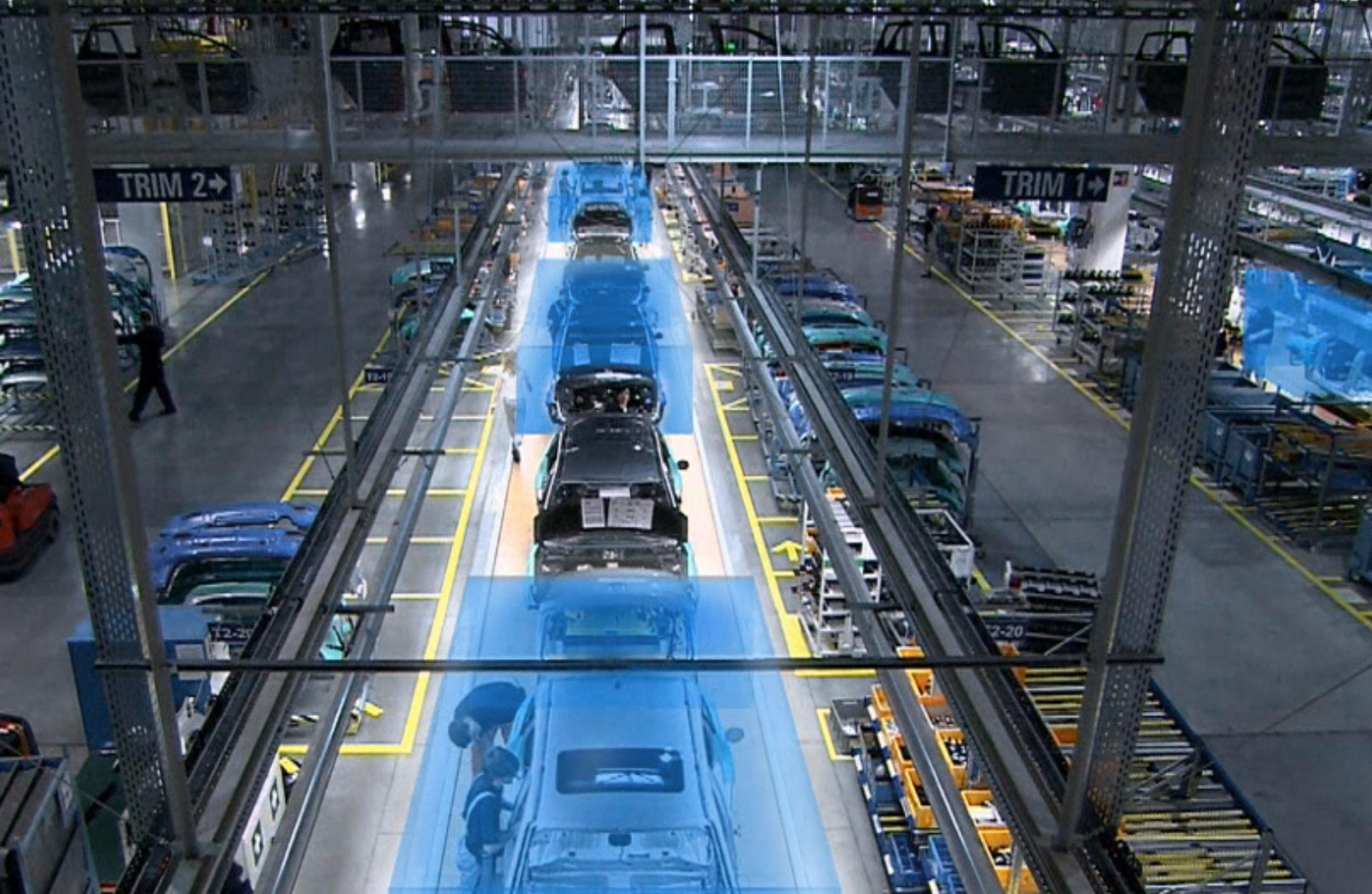

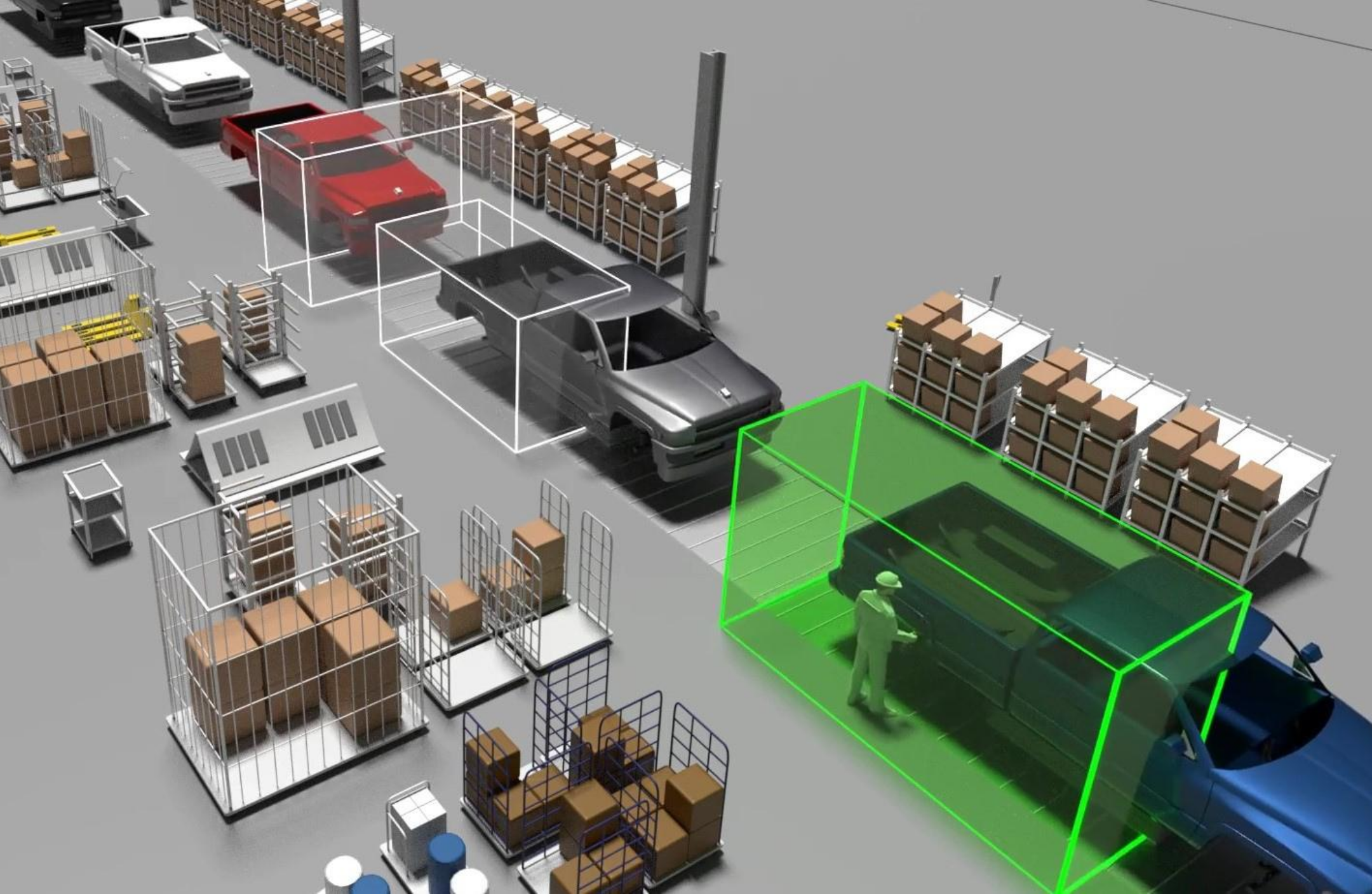

Steven Manifold2024-03-26T16:26:21+00:00On-demand Webinar Looking after us at work: where in the warehouse? In this webinar hosted by Cambridge Wireless, Helena Lisachuk of Deloitte and Andy Ward of Ubisense discuss the use cases for location technology in industry and why "There’s no single best sensor, just the best sensor(s) for the job". Location tech is indispensable for safety and optimisation in many industries, providing constant vigilance for misplaced machinery and orchestrating the precise ballet of robots