Transit Management Demo – Ubisense Virtual Conference 2023

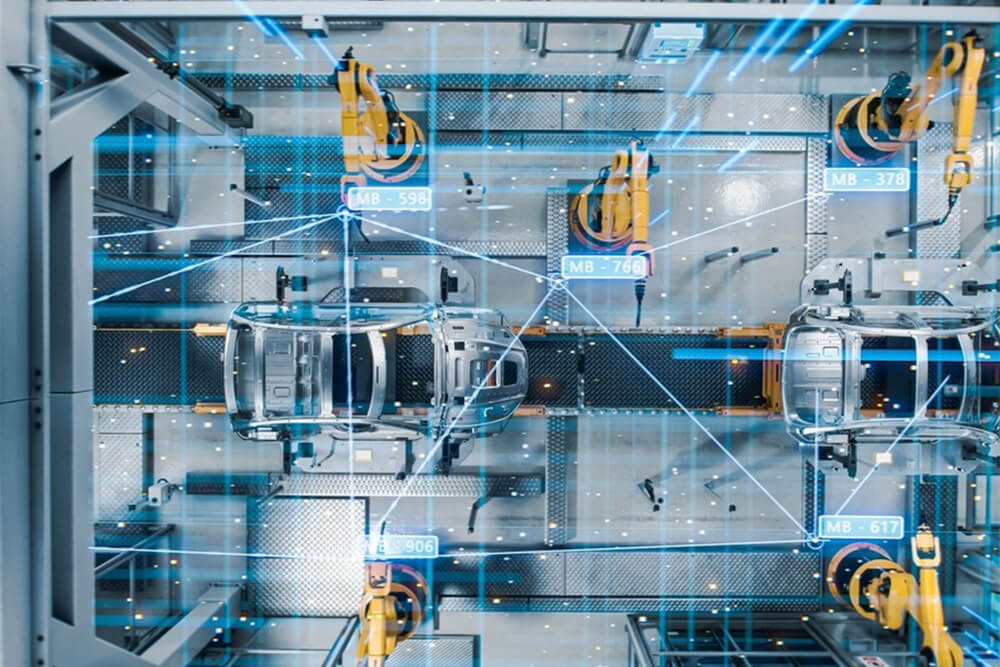

Mark2024-03-26T16:26:10+00:00On-demand Webinar Transit Management Demo - Ubisense Virtual Conference 2023 Evan Lin, Ubisense Presales Solutions Consultant, demonstrates how SmartSpace® can help improve and automate depot operations. Ubisense is a world leader in real-time location tracking. Our SmartSpace® and Dimention4™ technologies are making a global impact across a variety of industries, including mass transit, automotive, aerospace, logistics, and general manufacturing. In this video you will learn about: Ubisense in the Transit Industry 3rd party systems